- Home

- Resources

- Case Studies

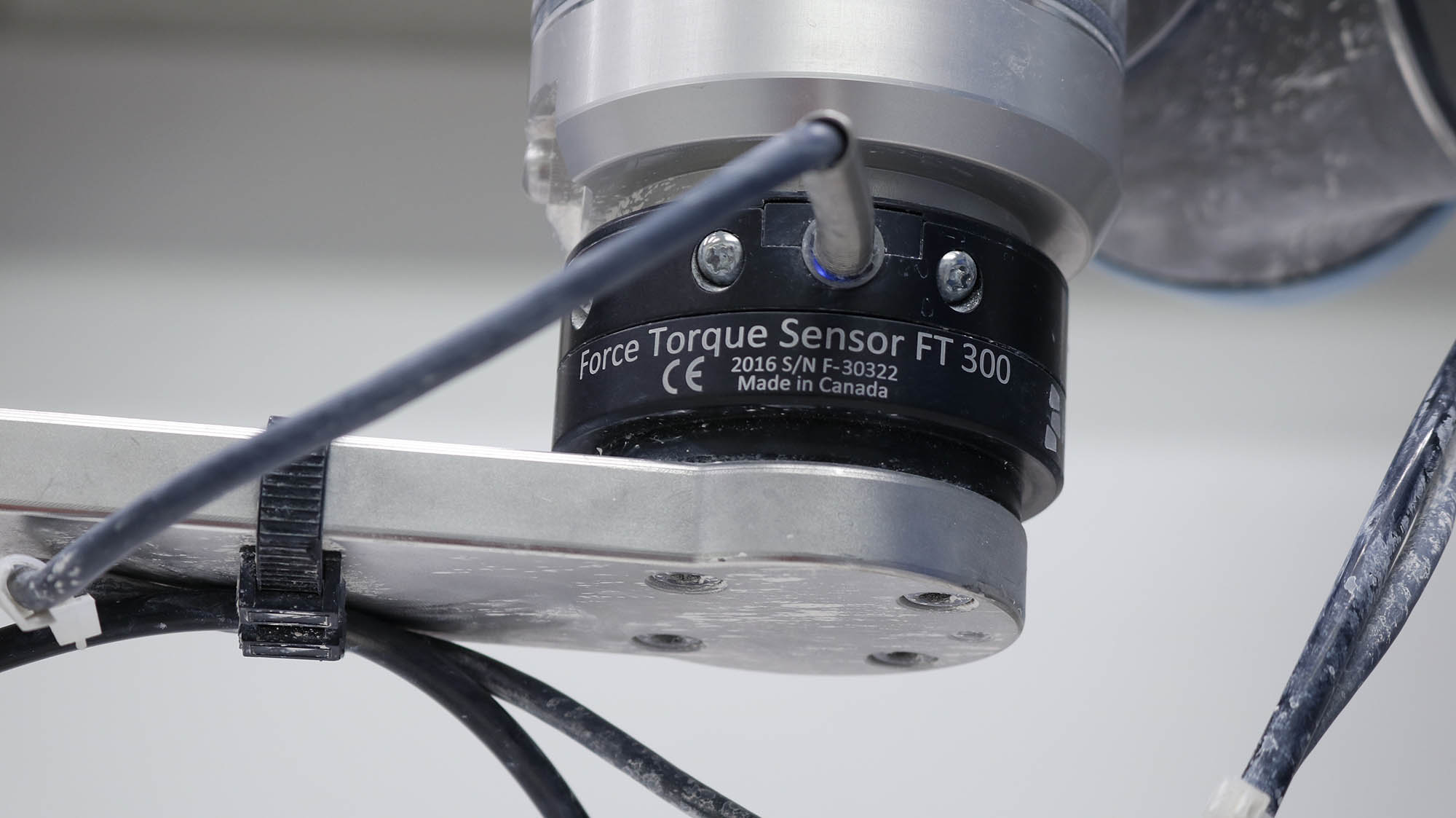

- Reduce Injuries and Increase Productivity with the FT 300 Force Torque Sensor

Reduce Injuries and Increase Productivity with the FT 300 Force Torque Sensor

Problem

At the Saint-Gobain plant in Sully-sur-Loire, France, human labor provides high-value work to the finished product. In their shift towards Industry 4.0 to free employees from repetitive tasks, Saint-Gobain wanted to automate a grueling glass polishing process, where a complex movement needed to be programmed for every different, small production series of glass.

Solution

With the path recording function of the Robotiq FT 300 Force Torque Sensor, the operator can grasp the device and make the movement; the Universal Robots UR10 then records and reproduces the operator's motion. The operator avoids frequent musculoskeletal disorders and focuses on the glass preparation, a painless, value-added operation.

Products they use

Applications

Finishing

Subscribe to the Robotiq newsletter

Get only relevant information about automation that’s of interest to you. No filler content. No unwanted emails. And you can unsubscribe at any time.