-1.jpg?width=1779&height=1000&name=Robotiq%20Background%20(Cascade%20Coffee)-1.jpg)

Case Studies

Cascade Coffee

How Cascade Coffee improved safety, performance, and employee satisfaction with six Lean Palletizing workcells

6500

Cases palletized in a day

5 min

The time to train an operator on the cobot

13 mo

Payback period for 6 palletizing units

About Cascade Coffee

Cascade Coffee is a 40-year-old company based in Seattle, Washington. Cascade is one of the largest contract roasting and packaging outfits in the US. They specialize in roasting, grinding, flavoring, and packaging coffee, and shipping it to different parts of the globe. Cascade’s customers span the world’s biggest food and beverage brands. Cascade’s production ranges from single-serve K-cups, 12, 20-ounce bags, and 2-pound bags out of their 150,000 square-foot facility. Their 120 employees are busy distributing to the US, Canada, and Japan.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

coffee

The Problem

Cascade Coffee used to palletize orders manually. A physically demanding process that was hampered by chronic labor shortages. Facing labor turnover and safety issues, Cascade faced the need to automate its palletizing operations.

The Solution

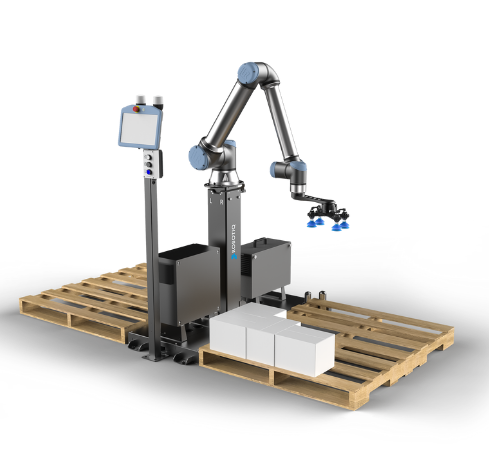

Robotiq and its partner, Olympus Controls, helped Cascade Coffe deploy six palletizing units, thus allowing Cascade Coffee to optimize its productivity as well as its safety and job satisfaction levels.

Unexpected wins.

Robotiq’s palletizing cobot brought benefits on many levels:

- Safety and team morale: It literally boosted Cascade employees’ happiness and motivation.

- Performance: Cascade considerably gained in performance, with their slowest line palletizing 2,500 cases per day and their fastest 7,500 cases per day.

- Raising the minimum wage: Employees who started on a temp basis as end-liners are now working as mid-liners, building their technical skills and earning more

The Robotiq solution

Palletizing

Robotiq’s Palletizing Solution and know-how allowed Cascade Coffee to optimize its productivity as well as its safety and job satisfaction levels. The result was an automated solution for which the ROI was about 13 months.