Founded in 1950, Caffè Corsini is an iconic name in Italian coffee, exporting to over 60 countries...

.png?width=1441&height=680&name=AdobeStock_301220431%201%20(2).png)

ADAPTIVE grippers

Get a grip on grippers:

Give your cobots their purpose, function, and performance

Adapt to any task with ease

When every second counts, your automation needs to keep up. Robotiq Adaptive Grippers are designed for flexibility, reliability, and seamless integration with leading cobot brands—now easier than ever. Whether you're handling delicate parts or heavier payloads, these grippers adapt instantly to your process, maximizing efficiency and minimizing downtime. With plug-and-play installation and intuitive programming, even first-time users can deploy them in minutes. Are you ready to boost productivity and future-proof your automation?

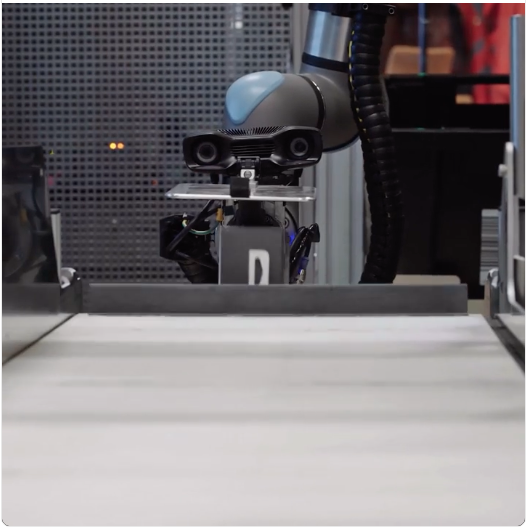

Meet Hand-E

Hand-E is a precise adaptive gripper solution for manufacturers in high-mix, low-volume environments. Its 50-mm parallel stroke makes it ideal for assembly tasks, while its sealed design ensures reliability in the toughest manufacturing conditions—including CNC machining.

Hand-E’s robustness makes it an ideal candidate for rugged environments. Its configuration is well-suited to production settings that involve minimal variation in object sizes.

-

7 kg

MAX PAYLOAD

IP67

IP RATING

50 mm

STROKE

Distinctive features transforming various applications

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

The go-to gripper for an infinite range of applications

Robust and adaptable

- From light to heavy industries.

- From tiny to big parts: wide stroke and high payload.

- From simple to complex shapes: fingertip kits and finger customization.

- From precision to high volume: adaptable, fast, and precise.

- From fast pick and place tasks, to dirty machine-tending and precise assembly tasks.

- For industrial needs: strong, fast, reliable, sealed.

- Easily replaceable fingertips allow for a perfect fit to each object.

- Dual-gripper configuration uses two grippers on the same robot, to reduce cycle times.

- Patented multi-grasp finger mechanism.

Simple and fast to deploy

- Quick-start kit compatible with Universal Robots and OMRON

- 5-min installation

- User-friendly configurations

- Complete supporting documentation and eLearning sessions

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Designed for a quick ROI

Robotiq’s Hand-E Gripper empowers users to take control. A simple configuration with minimal programming changes is all that is necessary for changeovers. By using a single gripper for multiple tasks, manufacturers can save time and money.

Design

The Robotiq Hand-E Gripper is production-ready. By opting for an off-the-shelf solution, you can achieve a faster return on investment and experience a quicker transformation and improvement in your operations. The product is delivered within 14 days of ordering.

Integrate

The plug-and-play interface ensures lightning-fast installation in 10 minutes or less. Robotiq offers plug-and-play products along with free coaching sessions and technical support, to minimize integration time and assist you with more complex setups.

Operate

The intuitive and powerful configuration interface makes it easy for any user-type to configure the gripper with confidence. The ergonomic shape is optimized for efficient robot hand-guiding.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

They trust Hand-E

What Robotiq’s grippers have to offer is a step beyond any of the competitors.

Vincent Roussy

Manufacturing Engineering Manager, Usinatech

We’re able to connect the grippers directly to the robot’s wrist, get feedback on the position and force, and check if there’s a part where there should be one—and whether it’s the right part.

Stephen Milchuck

R&D Manager, Fusion OEM

-

6500

Cases palletized in a day

Supporting documentation for a seamless experience

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Precision meets robustness

Payload 7 kg (15 lb) Gripper weight 1 kg (2 lb) Energy source Electricity, connected to robot wrist (24 V, 2 A) Control parameters Object detection, position, speed and force Warranty 5 000 000 cycles Stroke 50 mm (2 in) Grip force 20 to 185 N (4.5 to 41 lbf) Closing speed 150 mm/s (5.9 in/s) Repeatability 0.025 mm (0.001 in) Ingress protection (IP) rating IP67 Operating temperature -10 to 50 °C (14 to 122 °F) -

6500

Cases palletized in a day

The Hand-E gripper is Plug&Play with the following cobot brands.

Can’t find your cobot on our list? Our grippers work with all robots through industrial communication protocols. Visit our support documentation or talk to an expert to learn more.

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

The Iron Man Challenge

Norem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus. Maecenas eget condimentum velit, sit amet feugiat lectus.

Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Praesent auctor purus luctus enim egestas, ac scelerisque ante pulvinar.Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in)

Fingertips & Accessories

Did you know we offer a variety of fingertip options allowing you to grasp different shaped objects? Each gripper comes with different fingertips depending on the application and the robot arm you are looking to integrate with, and you get to choose among many other options. Plus, our Adaptive Grippers are easy to customize to your needs.

Meet Hand-E C10

Hand-E C10 is a concentric adaptive gripper solution for manufacturers in high-mix, low-volume environments. Its 40-mm stroke makes it ideal for assembly tasks, while its sealed design ensures reliability in the toughest manufacturing conditions—including humidity and dust (IP67 compliant).

-

10 kg

MAX PAYLOAD

IP67

IP RATING

40 mm

STROKE (DIAMETER)

Distinctive features transforming various applications

Machine tending

Pick & place

Precision assembly

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

The concentric gripper for an infinite range of applications

Robust and adaptable

- From light to heavy industries (IP67 - compliant).

- From tiny to big parts: wide stroke and high payload.

- From simple to complex shapes: fingertip kits and finger customization.

- From precision to high volume: adaptable, fast, and precise.

- From fast pick and place tasks, to dirty machine-tending and precise assembly tasks.

- For industrial needs: strong, fast, reliable, sealed.

- Easily replaceable fingertips allow for a perfect fit to each object.

- Dual-gripper configuration uses two grippers on the same robot, to reduce cycle times.

Simple and fast to deploy

- Quick-start kit compatible with Universal Robots and OMRON

- 5-min installation

- User-friendly configurations

- Complete supporting documentation and eLearning sessions

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Designed for multiple applications

Robotiq’s Hand-E C10 Gripper is ideal for tight spaces and industrial environments. Versatile with easily changeable fingertips and unlimited grasp options, it's plug & play for simple programming.

Design

The Robotiq Hand-E C10 Gripper is production-ready. By opting for an off-the-shelf solution, you can achieve a faster return on investment and experience a quicker transformation and improvement in your operations. The product is delivered within 14 days of ordering.

Integrate

True plug-and-play automation with smart features, easy integration, and quick delivery. Provides precise control and feedback through a simple visual interface, enabling fast deployment of robotic systems without advanced programming skills.

Operate

The ergonomic shape is optimized for efficient robot hand-guiding. Its factory-proven components require no maintenance for the first 2-5 million cycles. The software allows for part detection and position feedback, reducing downtime and enhancing reliability.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

They trust Hand-E

What Robotiq’s grippers have to offer is a step beyond any of the competitors.

Vincent Roussy

Manufacturing Engineering Manager, Usinatech

We’re able to connect the grippers directly to the robot’s wrist, get feedback on the position and force, and check if there’s a part where there should be one—and whether it’s the right part.

Stephen Milchuck

R&D Manager, Fusion OEM

-

6500

Cases palletized in a day

Supporting documentation for a seamless experience

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Precision meets robustness

Payload 10 kg (22 lbs) Gripper weight 1.7 kg (3.7 lbs) Energy source Electricity, connected to robot wrist (24 V, 2 A) Control parameters Object detection, position, speed and force Warranty 5 000 000 cycles Stroke (Diameter) 40 mm (1.57 in) Grip force (per finger) 25N to 175 N (5.6 to 39.34 lbf) Closing speed 14 to 107 mm/s (0.55 to 4.21 in/s) Repeatability 0.04 mm (0.002 in) Ingress protection (IP) rating IP67 Operating temperature -10 to 50 °C (14 to 122 °F) -

6500

Cases palletized in a day

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

The Iron Man Challenge

Norem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus. Maecenas eget condimentum velit, sit amet feugiat lectus.

Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Praesent auctor purus luctus enim egestas, ac scelerisque ante pulvinar.Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in)

Discover 2-Finger Grippers

The Robotiq 2-Finger Grippers stand out because of their exceptional adaptability and versatility. With two wide-stroke options of 85 mm and 140 mm, these tools grip an extensive range of objects. Their patented mechanical design allows for both encompassing and pinch grips, providing precise and powerful handling that leads to optimal performance in various applications.

These grippers excel in productions that demand precision, force, and adaptability on the go.

-

5 kg

MAX PAYLOAD

20 TO 235 N

GRIP FORCE

85 OR 140 mm

STROKE

Eliminate changeovers and reduce tooling costs

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

More than just parallel grippers

Simple programming

- Programmable stroke, speed, and force.

- One interface for all grippers.

- Programmable directly from the cobot device.

Great adaptability

- Replaceable fingertips allow for a perfect fit to each object.

- Dual-gripper configuration enables the use of two grippers on the same robot to reduce cycle times.

- Allows for both encompassing and pinch grips.

Swift integration

- Plug & play.

- Safe, ergonomic design.

- Cost-effective.

- Ready to produce.

Reliable operation

- Robust, factory-proven hardware.

- High pinch force and payload.

- Built-in part validation to confirm successful part grasping.

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Easy to integrate, easy to use

Robotiq's 2-Finger Grippers combine precision, efficiency, and versatility to optimize handling in manufacturing. Their seamless integration and smart control capabilities enhance productivity and reduce downtime. Durable and low-maintenance, they're adaptable for a wide variety of applications, where they significantly boost operational efficiency.

Design

Engineered for versatility, the 2-Finger Grippers are ideal for manipulating a wide range of objects. With adjustable force and stroke, they offer meticulous control for a large assortment of applications, such as pick-and-place and assembly. They also offer customizable fingertips and extenders to adapt to your specific needs.

Integrate

The 2-Finger Grippers seamlessly merge into your existing systems, minimizing downtime. Equipped with smart capabilities, they offer precise control over finger position, speed, and force, crucial for precise tasks. Their advanced part detection and feedback features ensure meticulous execution of operations, making them reliable in any automated setting.

Operate

The 2-Finger Grippers require minimal maintenance and ensure reliable operation in your production line. Through simple program modifications, they adapt effortlessly to different part shapes. The ability to easily swap fingers to accommodate various objects makes them an indispensable tool in efficient manufacturing environments.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

They trust Robotiq 2-Finger grippers

When customers come in, you look like you’re on the cutting edge of technology.

Tommy Caughey

President, Walt Machine Inc.

Robotiq has a unique solution: a reliable gripper that can manage part changeovers quickly, which is important for our high-mix, high-volume production.

Steven Nery

Manufacturing Engineer, Sennheiser Manufacturing USA

The 2F-85 is very intuitive in terms of force, opening, and activation. For everything pick-and-place-related, you can mount the fingertips however you want.

Joël Lessard

Director of Continuous Improvement, APN

We needed a very flexible gripper with which we could easily monitor force and the distance between two points. The 2F-85 was an obvious choice.

Marvin Plantius

CEO, KPE Engineering, Diehl

I didn’t have particular programming skills but I found it very easy, with some knowledge of logic, to program the robot, the 2-Finger Adaptive Gripper, and the Wrist Camera.

Adrian Iosif

Vice-President, Cascade

Mechanical Design Engineer, Assa Abloy

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

85-mm stroke, 5-kg payload capacity

Payload 5 kg (11 lb) Gripper weight 1 kg (2 lb) Energy source Electricity, connected to robot wrist (24 V, 2 A) Control parameters Object detection, position, speed and force Warranty 2 000 000 cycles Stroke 85 mm (3.3 in.) Grip force 20 to 235 N (4.5 to 50 lbf) Closing speed 20 to 150 mm/s (0.8 to 5.9 in./s) Repeatability 0.02 mm (0.08 in.) Ingress protection (IP) rating IP40 Operating temperature -10 to 50 °C (14 to 122 °F) Stroke 50 mm (2.0 in) -

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

140-mm stroke, 2.5-kg payload capacity

Payload 2.5 kg (5.5 lb) Gripper weight 1 kg (2 lb) Energy source Electricity, connected to robot wrist (24 V, 2 A) Control parameters Object detection, position, speed and force Warranty 2 000 000 cycles Stroke 140 mm (5.5 in.) Grip force 10 to 125 N (2 to 25 lbf) Closing speed 30 to 250 mm/s (1.2 to 9.8 in./s) Repeatability 0.03 mm (0.1 in.) Ingress protection (IP) rating IP40 Operating temperature -10 to 50 °C (14 to 122 °F) -

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

The 2F-85 & 2F-140 grippers are Plug&Play with the following cobot brands.

Can’t find your cobot on our list? Our grippers can work with any robot through industrial communication protocols. Visit our support documentation or talk to an expert to learn more.

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

End-of-line automation shouldn’t feel like a guessing game. Yet for many manufacturers, choosing...

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

The Iron Man Challenge

Norem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus. Maecenas eget condimentum velit, sit amet feugiat lectus.