Automatic integration

Our proven deployment approach, used by thousands of manufacturers

Can you really place the words “Lean” and “Robotics” together?

With today’s robots—more capable and easier to deploy—the answer is yes. Robotic cells can be part of your lean manufacturing and continuous improvement efforts.

Robotiq pioneered the Lean Robotics method and applies it across everything we do, from product development to cell deployment to world-class support. When you use Robotiq products and services, you benefit from a proven approach used by thousands of automation professionals worldwide.

Two principles make it work on the factory floor:

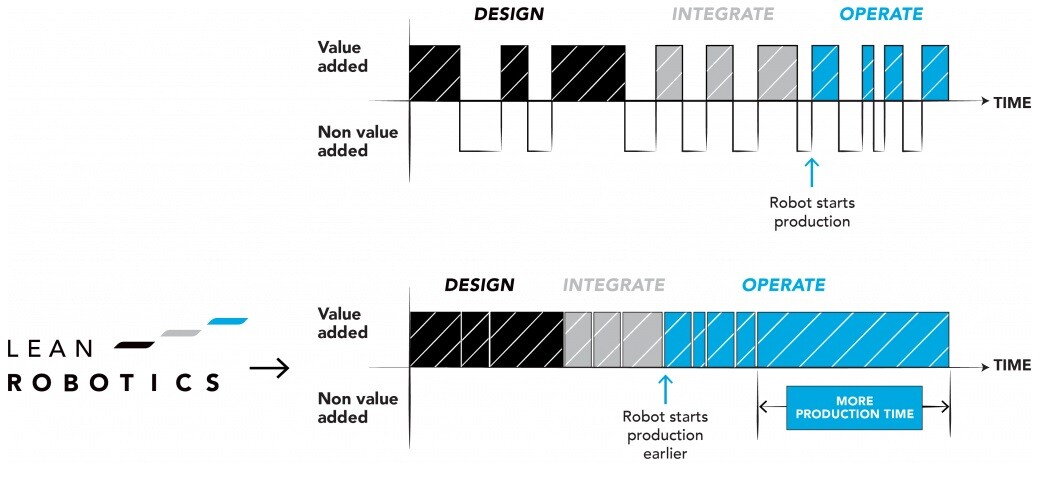

Automatic Integration makes integration automatic—not a custom engineering project, reducing cost, friction, and uncertainty so you get predictable outcomes from first deployment to scale.

Built-in Intelligence embeds intelligence into the full automation lifecycle, across software and hardware, delivering high-performance systems that are reliable and adaptable as needs change.

You can learn more by downloading the book for free or purchasing the hardcopy on Amazon.

How to simplify robot cell deployment?

Lean robotics is a systematic way to complete the robotic cell deployment cycle, from design to integration and operation. This methodology is detailed in a book written by Robotiq CEO Samuel Bouchard. This book is the result of a decade of the Robotiq team’s experience helping thousands of manufacturers overcome production challenges using robots.

How to design my robotic cell?

The Robotiq team is there to help manufacturers design their robotic cell. The first step is to map the process as it is now. Robotiq coaches and your local partner will then help you design your robotic cell.

-1.png?width=932&height=600&name=eLearning-logo%20en%20tete%20noir%20@2x%20(1)-1.png)