Robotiq

Lean Palletizing software

Simple where it matters, powerful where it counts.

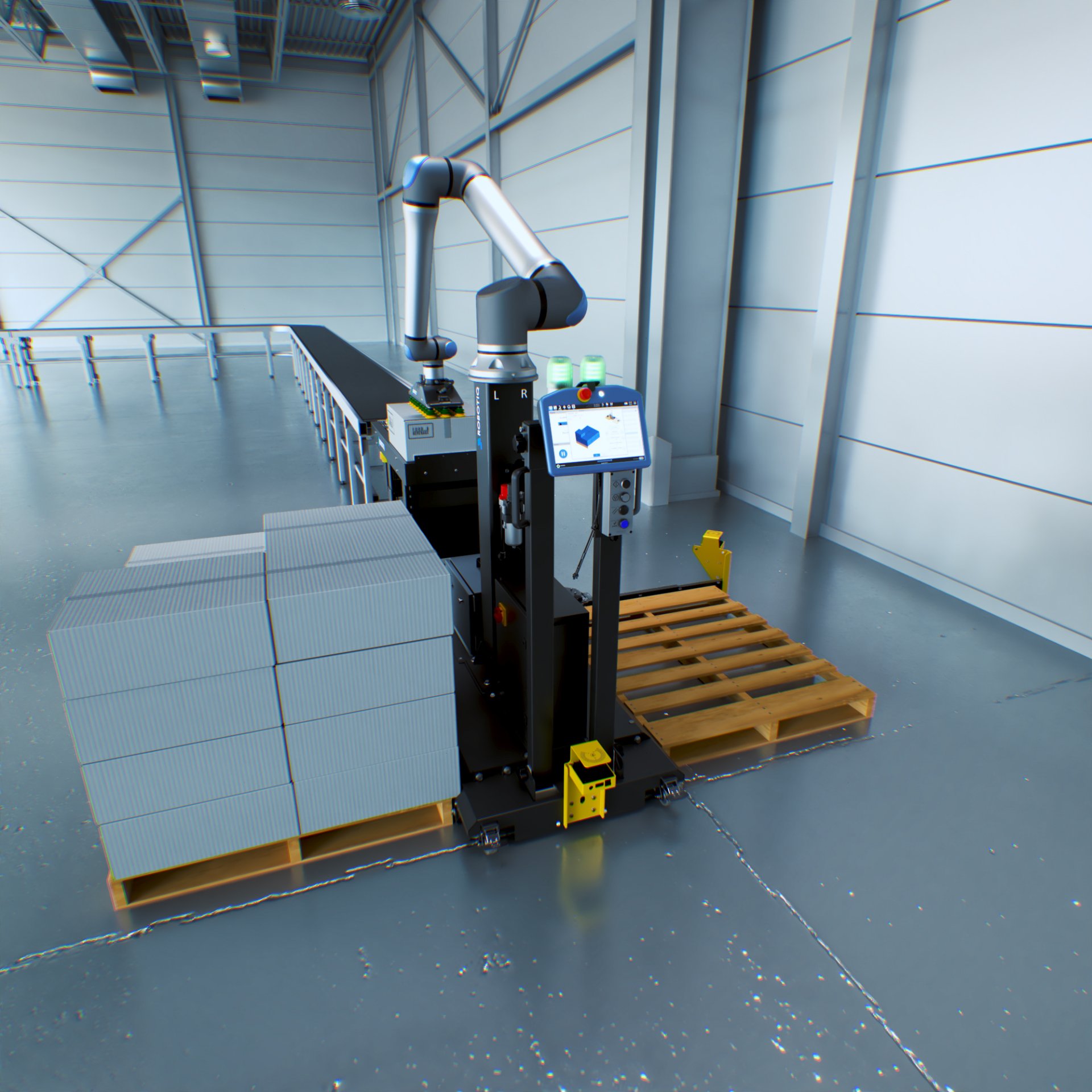

Robotiq is the leader in collaborative robot palletizing solutions worldwide. This experience is enabled by Lean Palletizing software, the intelligence at the core of the solution.

With nearly 1 000 palletizing units deployed across food and beverage and other industries, the software delivers simple operation, adaptive control, and optimized performance to reduce downtime and scale palletizing automation.

Smarter path generation with AI

Robotiq Lean Palletizing software is designed for real-world factory floors. Ones with tight layouts, low ceilings, obstacles, and limited reach.

With Advanced Collision Avoidance, our proprietary AI-based motion planner (RRT) evaluates thousands of possible paths in seconds to generate the most efficient, collision-free trajectories when required in compact cells, high stacks, or complex patterns.

You get faster cycle times, safer motion, and predictable performance without redesigning your layout.

Out-of-the-box optimized trajectories

Robotiq’s Lean Palletizing software delivers optimized trajectories the moment you launch a project, so there's no manual tuning, no expert programming. Whether your priority is faster cycles for higher throughput or gentler motion for longer equipment life, the system automatically adapts motion strategy to your goals.

Our built-in AI understands the robot’s workspace and surrounding objects, then automatically adjusts trajectories to avoid collisions and keep motion smooth and reliable. No manual fine-tuning.

Scalable by design

Robotiq gives you an open, flexible interface that scales from simple cells to multi-line deployments, all using the same software. No black boxes, no lock-in.

Add tasks like traceability, quality checks, or box rejection using standard UR language. Our platform stays fully compatible with all UR functions and UR+ products, so you can customize without complexity.

Start with a ready-to-go program, then expand as your needs grow.

One platform. Many applications. Scaled your way.

Built to adapt

Variable pallet height

Robotiq’s Lean Palletizing software automatically adapts to variable pallet heights, keeping production running with consistent, robust stacking.

The built-in force sensor also enables Box Contact Detection, using automatic force control to gently mate boxes before release for high quality pallets.

Built to adapt

Create a new recipe

Create and deploy new palletizing recipes in minutes, without calling an integrator.

Seasonal products, new SKUs, or packaging changes can be handled directly by a maintenance technician or a trained operator.

Create as many recipes as you need to support your production.

Built to adapt

Recover from a protective stop

Unexpected events happen on the factory floor. When a palletizer enteres a protective stop, Robotiq Lean Palletizing software makes recovery simple and safe.

The system guides operators and technicians through an autonomous restart, allowing production to resume quickly without external support.You get less downtime, faster recovery, and a palletizer that’s ready to get back to work.

Easy-to-operate

Choose a recipe

Start production in seconds.

With just a few simple steps and clear button box controls, operators can confidently select a recipe and start palletizing.

Everyday operation made easy.

Easy-to-operate

Operator pallet change

Pallet changes are simple and safe.

When entering the safety zone, operators can choose Reduced Mode, allowing palletizing to continue on the other pallet at a safe reduced speed, or a Safeguard Stop to fully stop the system.

You get safer pallet changes with minimal downtime.

Ready when you are!

See what fits best

Want to see if a Robotiq Palletizer fits your operation? Answer a few questions and we'll show you which setup works best for you along with a ROI calculation, price range and 3D simulation