Case Studies

Fusion OEM

Fusion OEM doubles production capacity in CNC machining operations

4

Collaborative robots deployed

50%

Reduced delivery delays

9

CNC machines automated

About Fusion OEM

Fusion OEM is an award-winning, CNC systems integrator for collaborative robots, focused on automating machine tending solutions for CNC turning and milling machines to increase productivity. Here’s a story on how employees brought the idea of robots to their managers.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Fusion OEM Doubles Production Capacity in CNCMachining Operations

I can spend more time programming machines since I don’t have to load them. Plus, there’s more consistency in the loading. It’s taken away some of the human error.

Brian Wrobliski

Machinist, Fusion OEM

Overcoming Challenges: Our Solutions

The Problem

Fusion OEM is a small machine shop in the Chicago area. Named one of Forbes’ top 25 small American companies in 2017, it has always aimed to stay ahead of the game through innovation. But recruiting a good machinist in the Chicago area is a tough task for any machine shop.The Solution

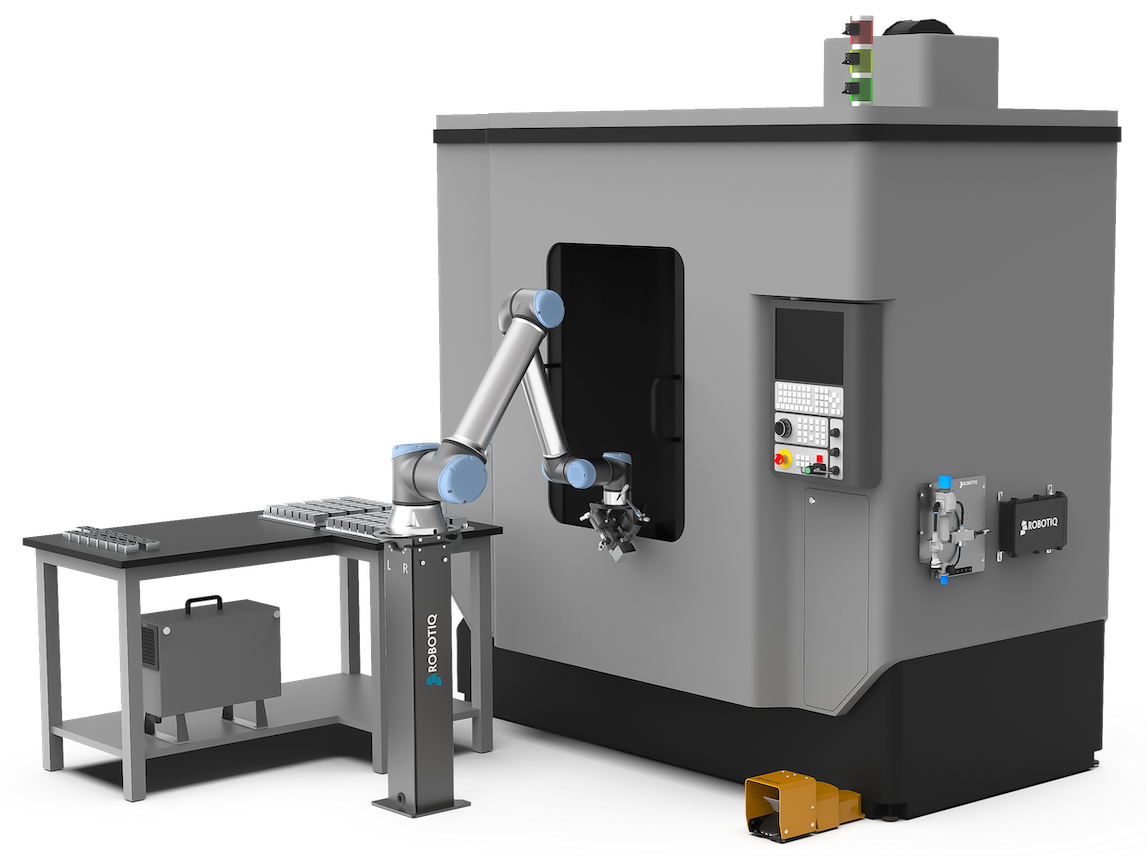

Head machinist Davin Erickson saw a video of a collaborative robot tending a CNC machine on social media and immediately set about convincing CEO Craig Zoberis to buy one. Now—one year later—Fusion OEM has four Universal Robots equipped with Robotiq’s Hand-E Adaptive Grippers, Force Copilot software for simple force control programming, and Insights monitoring software to improve production capacity.

The Results

Automating 9 CNC machines.

Robotiq’s Machine Tending Solution brought benefits on many levels:

- Production increase: Within the next year, the team members hope to double production capacity, increase machine uptime and—above all—continue to maximize their human potential.

- Collaborative: Humans and robots are getting along pretty well. For machinists these robots are just like any other equipment inside the shop.

- Easy to use: The Robotiq Machine Tending Solution is easy to use and to program. Every new program can be operating in minutes.

The Robotiq solution

Four Robotiq Machine Tending cells were deployed at Fusion OEM within less than a year. A process made easy thanks to the use of Force Copilot.

Applications

Machine Tending

At Fusion OEM, employees found a way to increase productivity by adding four Universal Robots, equipped with Robotiq’s Hand-E, Force Copilot, and Insights, over the span of a year. Running a job with this setup is now four times cheaper than operating manually.