.jpg?width=2000&name=Photo_Screwdriving%20Solution_Screwdriver%20(1).jpg)

Tightening up efficiency

Robotiq Screwdriving Solution

The Problem

Assembly unreliability

Screwdriving in assembly is essential, yet prone to human error, risking product damage, a hit to your reputation, and revenue loss. In assembly lines, where workers are hard to find, it affects motivation and raises the risk of strain injuries, which makes workforce reliability even more challenging.

THE SOLUTION

Minimize errors

Automating screwdriving minimizes human errors and boosts product quality, customer trust, and revenue. It also frees workers to focus on more stimulating tasks, which positively impacts employee retention and improves overall production efficiency and reliability.

Presentation

Meet the Robotiq Screwdriving Solution

The Robotiq Screwdriving Solution is a robust, all-in-one system designed for the automation of small assemblies. Equipped with a versatile vacuum system that handles screws of any material, it features an intuitive, easily adjustable screw feeder and a compact, lightweight screwdriver with extended reach capabilities.

This off-the-shelf solution, encompassing every part in a single SKU, not only simplifies automation but also enhances precision and efficiency on the assembly line.

Robotiq's difference

Handles assembly tolerances

The system can handle imperfect inputs, like screw, part, and jig tolerances, by self-adjusting to assembly variances. This means the automation conforms to your existing assembly setup, rather than requiring adjustments to it.

Includes built-in error-proofing

The screwdriving solution detects assembly errors like screw defects and missing or extra parts. Its toolbox of pre-programmed features enables autonomous error recovery, boosts reliability, and cuts programming time.

Enables 5-minute changeovers

The solution is designed for deploying quickly and adapting easily to product changes. In a few steps, the system is ready to assemble different screws on different products, which facilitates the automation of small batches.

Discover what the Robotiq Screwdriving Solution can do for you

Specs & components

Screwdriver SD-100

| Torque range | 0.3 Nm to 4 Nm (2.66 in-lb to 35 in-lb) | ||

|---|---|---|---|

| Screw diameter | M2.5 (#3) to M5 (#10) | ||

| Speed | 1 to 600 RPM | ||

| Air consumption | 65 l/min | ||

| Weight | 1.5 kg (3.3 lb) | ||

| Dimensions | 272 mm x 143.5 mm x 75 mm (10 3/4 in. x 5 5/8 in. x 3 in.) |

Screw feeder SF-300

| Screw diameter | M2.5 (#3) to M5 (#10) | ||

|---|---|---|---|

| Screw length | 6 mm (¼ in.) to 25 mm (1 in.) | ||

| Typical feed rate | 3 s per screw | ||

| Screw chamber volume | 300 cc | ||

| Dimensions | 157 mm x 286 mm x 171 mm (6 3/16 in. x 11 1/4 in. x 6 3/4 in.) |

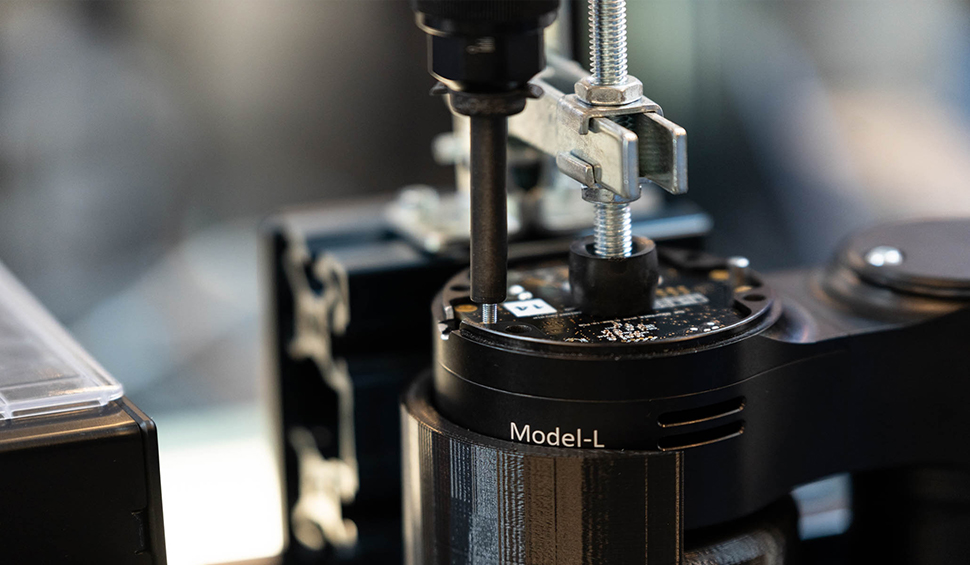

Screwdriver

The Robotiq Screwdriver SD-100 features a robust vacuum system for transporting various materials and compliant sleeves for precision insertion, all in a compact, controller-free design ideal for tight spaces.

Screw Feeder

The Robotiq Screw Feeder SF-300 is designed for easy adaptation to different screw sizes. It features a large-capacity chamber, dual sensor functionality, and a durable industrial-grade exterior.

Force Copilot

Robotiq's Force Copilot technology simplifies programming by automating force-sensing capabilities and seamlessly integrating communication among the screwdriver, screw feeder, robot, and vacuum technology.

Robotiq-certified bits

Robotiq-certified bits are designed to enhance precision and reliability in automated applications.

Vacuum sleeve kit

Vacuum sleeves are tailored to support a wide range of screw types, ensuring versatility and efficiency in your automated processes.

Software

The Robotiq Screwdriving URCap integrates the force sensing and force control functions to automatically program a pick and a screw, but the program tree is open for you to develop any advanced programming sequence.

Process

Designed for flexibility

The Robotiq Screwdriving Solution is a one-stop shop for assembly line automation. It combines advanced technologies like force sensing and efficient screw feeding, is deployable in just two weeks, and occupies a minimal footprint.

Find out if the Robotiq Screwdriving Solution is compatible with the specifics of your application.

Simplifying integration for complex processes

The Robotiq Screwdriving Solution makes complex integrations straightforward. Intuitively deploy and replicate across your operations, increasing efficiency without hefty investments.

The URCap software simplifies configurations through pre-programmed functions that only require minimal data entry.

Ensuring reliable operation

The Robotiq Screwdriving Solution is designed for quick 5-minute production changeovers. Error-proofing features like auto screw detection and torque control ensure high-quality output without any programming expertise. Plus, comprehensive eLearning resources support your workforce's rapid skill development.

Case Studies

Empower people in assembly functions

Few assembly functions are as closely linked to debilitating injuries, employee disengagement, and labor scarcity as screwdriving. Robotiq Screwdriving Solution’s pre-engineered modules simplify and accelerate installation to quickly address workforce strain.

The Screwdriving Solution addresses high turnover and labor shortages, allowing skilled workers to tackle more complex tasks. It also increases employee engagement by focusing staff on critical areas where human expertise is essential, which contributes to business success.

Boost productivity

The Robotiq Screwdriving Solution is key to maintaining efficiency, throughput, and quality in assembly lines, ensuring every cycle is precise. It unlocks automated assembly by allowing you to place and screw parts, which provides a boost to cell output, consistent quality assurance, and uninterrupted production—even without operators.

By automating screwdriving, the solution minimizes human error. This protects your products and revenue while reducing operator fatigue and labor costs, leading to consistent quality and a swift return on investment.

.jpg?width=1374&height=1374&name=Photo_Screwdriving%20Solution_Screwdriver%20picking%20screw%20from%20feeder%20(1).jpg)

Embrace adaptability

The Robotiq Screwdriving Solution transforms factory operations with its adaptability, which lets you swiftly adjust to unique demands and market shifts. Suitable for any industry and business size, it handles diverse screw types and excels in tight spaces.

Its easy configuration and flexible tooling enable rapid changeovers, allowing for production adjustments in under five minutes. This investment boosts your factory's agility, competitive advantage, and scalability.

Gallery

-1.png?width=932&height=600&name=eLearning-logo%20en%20tete%20noir%20@2x%20(1)-1.png)