Case Studies

Korea Pelagic

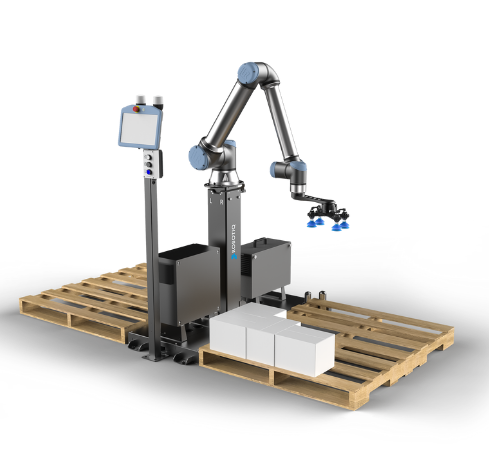

How automated Palletizing helped Korea Pelagic solve labor shortages challenges and increase productivity by 200%

2 m

Pallet height

200%

Increased Productivity

3

Partners for exceptional collaboration

About Korea Pelagic

Korea Pelagic is a seafood product company that has been in business since 2006. The company is tech-focused, using e-commerce, digital marketing, and the latest production technologies to bring innovative solutions that suit the modern world. Operating three packaging facilities in Busan, South Korea, the company employs over 100 people across its headquarters and outsourced personnel. They also operate a factory in Indonesia. The company specializes in packaging and palletizing frozen fish. Korea Pelagic’s mission is to provide fast delivery to ensure customers receive the best quality and fresh products.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Overcoming Challenges: Our Solutions

The Problem

Korea Pelagic was looking for ways to solve labor challenges and improve its palletizing process. The labor shortages were particularly affecting the palletizing task, which involved stacking boxes 2 meters high in a cold environment. A difficult and unrewarding task which resulted in a high turnover.The Solution

Korea Pelagic used the Robotiq Palletizing Solution to optimize their palletizing process, reduce the strain on their workforce, and increase productivity by 200%.

The solved challenges.

Robotiq’s palletizing cobot brought benefits on many levels:

- Employee adoption: The workers are happy to work alongside the robot, seeing that it is trustworthy and reliable. By automating the palletizing task, they are able to put those workers to better use in more rewarding tasks.

- Productivity: After the robot was up and running, Korea Pelagic found they had increased the palletizing production by an impressive 200% compared to manual palletizing.

The Robotiq solution

Palletizing

The Robotiq Palletizing solution transformed Napco’s operations: not only did it lead to a 15% increase in production, but it also reduced the risk of injuries and allowed the company to reallocate eight workers per day to more specialized tasks.