Case Studies

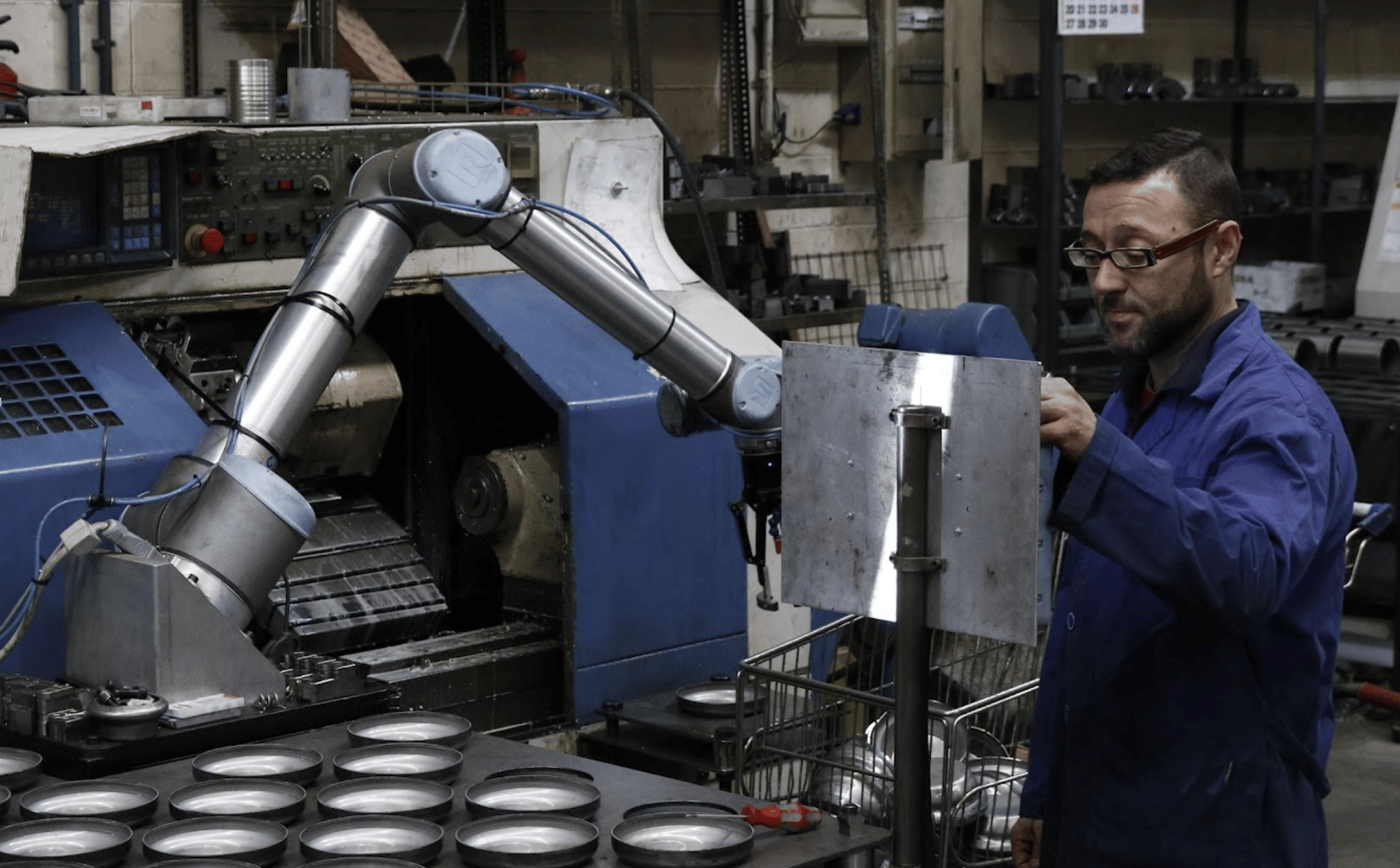

Portas Euro-Rapid

Portas Euro-Rapid doubles machine tending capacity with 2F-140 Adaptive Grippers

3

Machines operated at the same time

5

Day integration

50%

Increase productivity

About Portas Euro-Rapid

Portas Euro-Rapid manufactures fittings and couplings to join pipes together. The processes executed in their facilities include the design, construction, and manufacture of a variety of flanges, fittings, pipes, and crimping ferrules. These components are essential for the conduction of fluids and for creating connections between pipes/tubes and hoses.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Portas Euro-Rapid Doubles Machine Tending Capacity with 2F-140 Adaptive Grippers

The whole integration went very smoothly. Half our staff is over 40 years old, and everyone found it easy to learn to work with Robotiq and Universal Robots.

Joaquim Portas

President, Portas Euro-Rapid

Overcoming Challenges: Our Solutions

The Problem

Portas Euro-Rapid manufactures fittings and couplings to join pipes together. Mechanical flaws slowed machine operations, causing a lot of downtime with limited personnel available to fix issues.The Solution

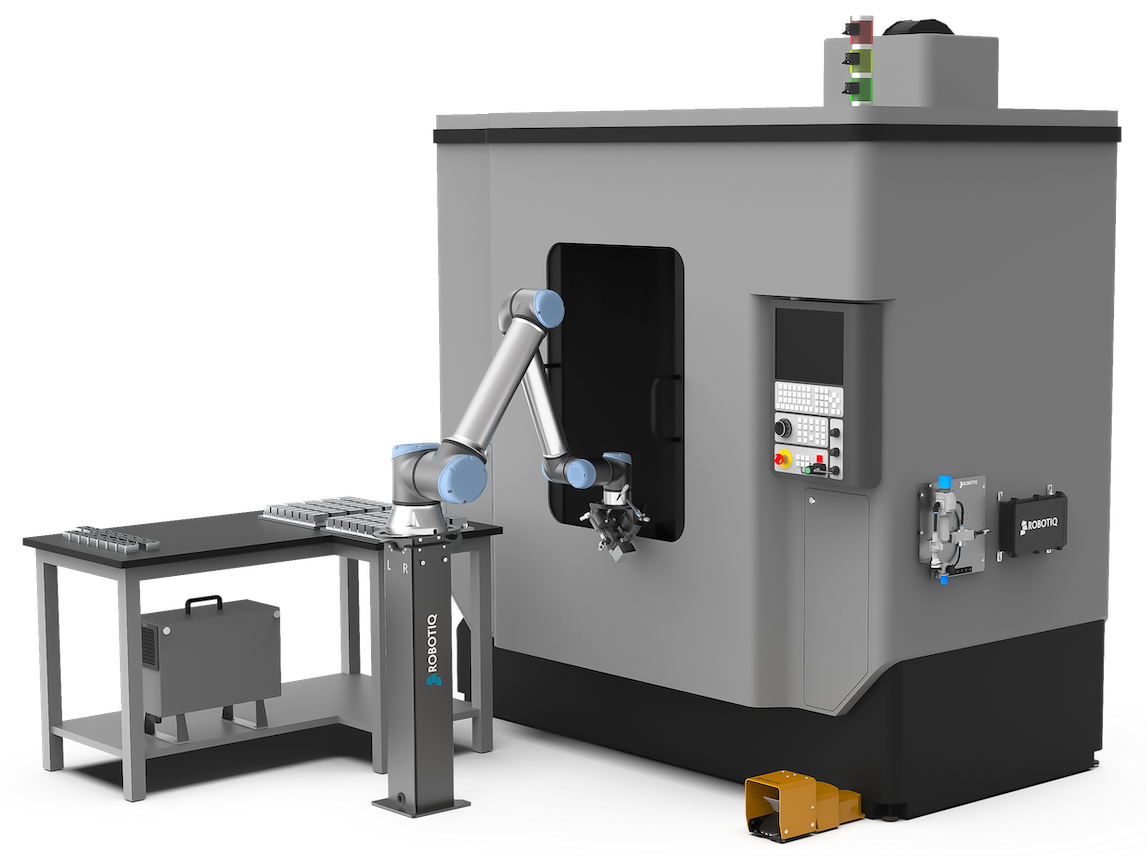

Integrating Robotiq 2F-140 Adaptive Grippers and Universal Robots UR10 to each machine allowed each employee to take care of three machines. Now their machines run full-time and production capacity has doubled.

The Results

Lean robotics at their best.

Robotiq’s Machine Tending Solution brought benefits on many levels:

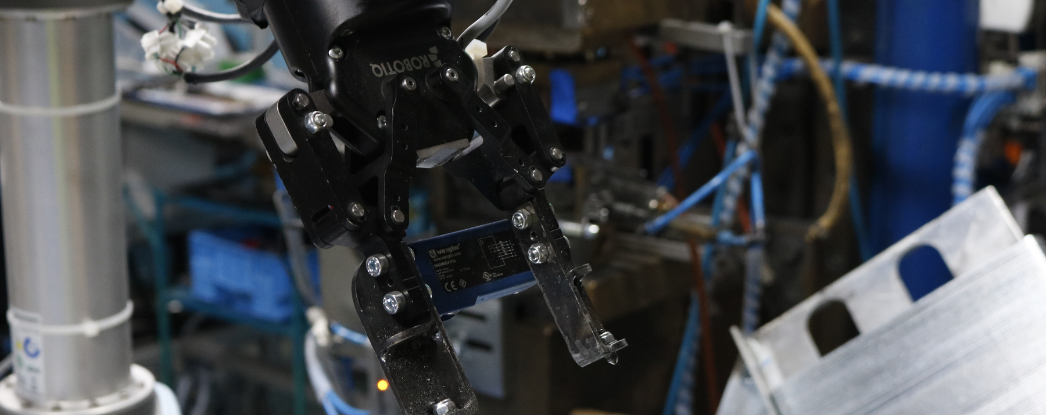

- Design: Robotiq 2F-140 Adaptive Grippers allowed to program different positions and tailor them perfectly for each part of the process.

- Integrate: The integration took less than a week. Most employees didn’t know anything about robots. They spent a few hours learning how to program, how to make the grippers work, and how the machines had to work.

- Operate: Now their machines run full-time and production capacity has doubled.

The Robotiq solution

Mechanical flows slowed machine operations, causing a lot of downtime with limited personnel available to fix issues. Integrating Robotiq 2F-140 Adaptive Grippers and Universal Robots UR10 to each machine allowed each employee to take care of three machines.

Applications

Machine Tending

Portas Euro-Rapid saw the effects of Robotiq’s Machine Tending Solution immediately: the managed to have one worker operating three machines at the same time, and double the production capacity.