Intelligence made physical

Robotiq turns intelligence into real-world automation. Intelligence Made Physical reflects our DNA: intelligence is built into our software and hardware from the start, enabled by Automatic Integration and proven in production. AI now amplifies that embedded intelligence to deliver predictable results from first deployment to scale.

The real impact of automatic integration

Empower People

- Provide a safer and injury-free workplace.

- Turn your labor scarcity into opportunity.

- Empower your workforce: From repetitive tasks to value-driven roles.

Boost Productivity

- Increase your productivity and profits.

- Reduce your costs and downtimes.

- Enhance quality with consistent output and reduce manual errors.

Enhance Adaptability

- Stay agile, adapting the system to your changing needs.

- Be equipped to scale up with standard technology.

Find out why we’re best-in-class

Automatic Integration

Integration is automatic, not a custom engineering project.

Custom integration creates cost, friction and uncertainty before deployment.

Robotiq makes automation work out of the box and scale across your operations. Automatic Integration frees human hands from repetitive tasks, while workcells and physical AI modules deploy fast, perform reliably, and consistently beat manual labor.

Built-in Intelligence

Intelligence is built into every part of the system.

Intelligence is embedded into the complete automation lifecycle and embodied in the software and hardware modules.

When intelligence is added after the fact or forgotten in critical elements, performance and reliability remain uncertain.

Our built-in intelligence keeps systems flexible and ready for change, turning complex automation into predictable, high-performing solutions.

Our standard solutions

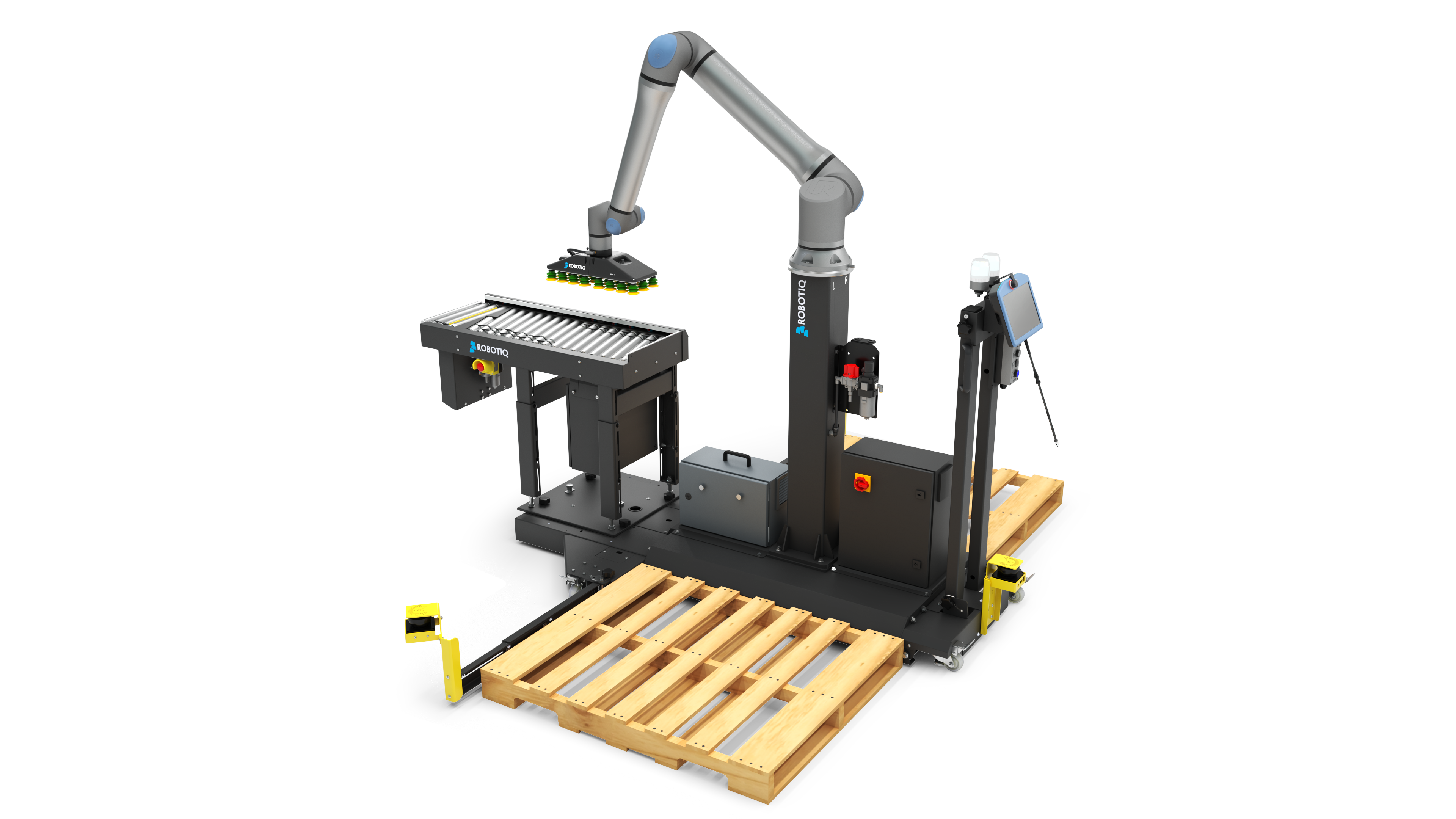

Lean Palletizing

Dive into the world of hassle-free automation. With a few minutes of setup, achieve immediate robotic actions. Expertise in robotics? Not required!

More

Machine Tending

Optimize productivity and ensure the continuous operation of your machines with minimal downtime, providing you with peace of mind.

More

Screwdriving

Achieve precision and reliability in every task, simplifying even the most intricate small-screw assembly processes with unmatched efficiency.

MoreOur components

Real stories from our users

How Glenhaven Scaled with Robotiq Palletizing Solution and Installation Services for Oven-Ready Meals

Explore how Glenhaven optimized operations, reduced labor dependency, and set the foundation for continued growth by implementing Robotiq’s PE20 Palletizing Solution.

The simplicity of the cobot for users was one thing that appealed to me, and how it was user-friendly.

Stephen Murphy

Project Manager, Glenhaven

Family-owned and operated Deanan Gourmet Popcorn scales up operations with Robotiq Palletizing Solution.

Discover how Deanan Popcorn had minimal impact on their current layout, a quick install and scalability with Robotiq Palletizing Solution.

It doesn't have the big cage around it, and the footprint is so small, like it's half a pallet, and it's movable. Those two things sold me right away. On top of that, it had a third of the budget that all the other robot companies had proposed.

TREF HODGE

Chief Operations Officer, Deanan Gourmet Popcorn

Eckerts GmbH improves productivity while guaranteeing top-quality spirits production

Discover how this solution now manages the handling of fragile cartons, reducing manual labor and creating a safer, more efficient workflow for employees.

This solution is one of the best things we have bought in recent years. The system has been running flawlessly from day one.

Andreas Klemp

Production manager, Eckerts GmbH

Raumland GmbH improves efficiency while maintaining high-quality wine production

See how this solution now handles over 5M bottles and 2,500 varieties of wine per year, relieving employees of manual labor.

The cobot perfectly reflects what we need. It is a flexible machine, compact, quick to set up, and, ultimately, affordable. We were able to automate a task that was extremely tedious. No one complains about back pain anymore. At least not from palletizing.

Sebastian Raumland

Managing Director, Raumland GmbH

Hack AG has effectively transformed its palletizing operations into a more efficient, adaptable and user-friendly system

Learn how the Robotiq Palletizing Solution handles 800 SKUs and moves between lines in just over 8 minutes.

The key result for our production process is that we are now further flexible in our processes and product planning, and we decreased the hard work of our employees.

Simon Gunnemann

Managing director central production, Hack AG

Discover the real-world applications of Robotiq

How Cascade Coffee increased safety, performance, and employee satisfaction using Robotiq's Palletizing Solution.

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

-2.png)

1_2026_Siemens_UR_demo_CES2026.gif)