Case Studies

APN

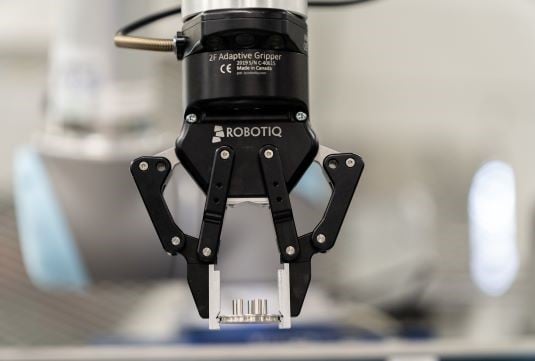

Increase CNC machine uptime with Robotiq’s 2F-85 and wrist camera

300

Different parts to handle

15%

Uptime increase

1 year

ROI

About APN

Founded in 1970 in Quebec City by Claude Proteau, APN has developed expertise in the production of high-quality precision parts. APN has become one of the most efficient machining companies in North America. APN Global today has several production sites offering products of unmatched quality and precision.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Increase CNC Machine Uptime with Robotiq’s 2F-85 and Wrist Camera

The robot handles any of our 300 different parts with a single parametric program. When we make a change, we only have to do it once.

William St-Germain

Automation Engineer, APN

Overcoming Challenges: Our Solutions

The Problem

APN manufactures high-precision parts for the aerospace industry in Quebec City, Canada. To stay competitive in this field, they needed to increase machine uptime—with the ultimate goal of one dayThe Solution

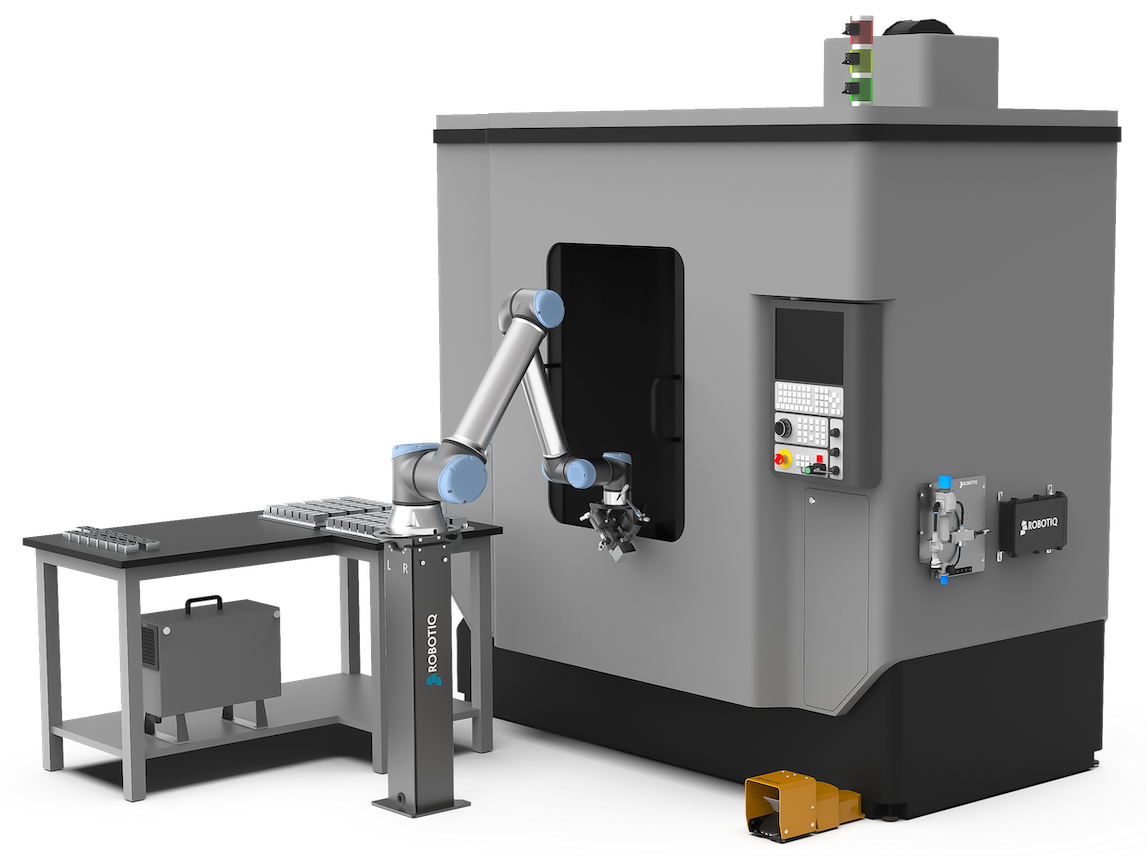

APN automated the parts-handling task with Universal Robots UR5 and Robotiq 2F-85 Adaptive Gripper and Wrist Camera. After spending a year fine-tuning their first robotic cell, they replicated it eight times in four months.

The Results

Automating CNC machines.

Robotiq’s Machine Tending Solution brought benefits on many levels:

- Complex tasks made easy: Robotiq’s Wrist camera offered APN the possibility to efficiently and easily detect around 300 different parts.

- Wide stroke: 2F-85, allowed to handle their 300 different types of parts. The gripper’s configuration is very intuitive in terms of force, opening, and activation.

- Easy to program: APN is glad to be able to operate with a single, parametric program.

The Robotiq solution

To get more out of their nine CNC machines each day, APN automated the parts-handling task with Universal Robots UR5 and Robotiq 2F-85 Adaptive Gripper and Wrist Camera.

Applications

Machine Tending

APN needed a technology that could efficiently detect many parts, since their programs process around 300 different parts. Only the Robotiq Machine Tending Solution could do it with easy programming.