Case Studies

TIDI Products

How TIDI products revolutionized their process with five Robotiq Palletizing Solutions

30%

On the first deployment

25%

On subsequent deployment

2X

Performance on the combined workcell

About TIDI Products

TIDI Products is deeply committed to supporting caregivers and protecting patients. With over 50 years of experience, the company has been providing quality solutions to healthcare professionals across the globe, helping reduce the risk of contamination and improving patient care. The company has a global presence, with facilities in the United States, China, and Mexico, and distribution partners worldwide. It employs over 2,000 associates across all locations and 400 at its headquarters in Neenah.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

TIDI Products revolutionized their processes with 5 Robotiq Palletizing Solutions

If I was to go back in time to give myself some advice, I’d say ‘Do it sooner.’ Sure, there are upfront costs, but it’s very easily justifiable and it’s very beneficial to the business and people

Cameron Lemke

Value Stream Manager

The Problem

One person, two separate tasks: filling AND palletizing boxes. Inefficient operationally, undesirable workwise. Production slowed, delivery deadlines blown, and orders turned down due to backlog, resulting in revenue losses.The Solution

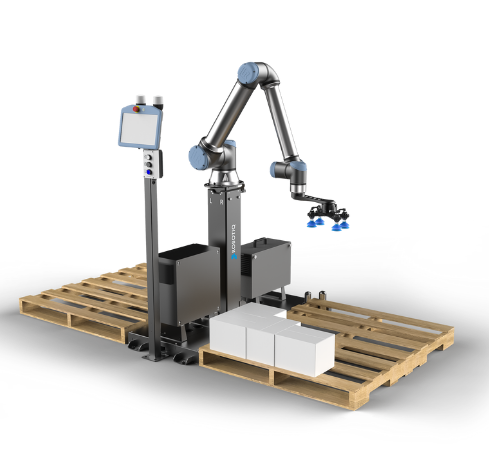

TIDI Products upgraded to end-of-line automation. Picked Robotiq for their user-friendly software tool, AX Series cobot and 7th axis coordinated motion, and incorporated five palletizing units across their production lines.

The Results

The Robotiq solution

Robotiq's Palletizing Solution provided TIDI Products with the flexibility they needed for various applications.

- Safety and consistency: Reducing the physical strain on workers means they can stay healthy and productive for longer.

- Flexibility: Robotiq Palletizing Solution’s user-friendly interface also allowed operators to gain control over robotic processes quickly and intuitively.

- Productivity: The productivity gains from the first palletizing cell were 30%, which is very impressive. Subsequent cells have increased by a similarly impressive 25%.

Applications

Palletizing

Robotiq’s Palletizing Solution brought about remarkable results to the company’s US Wisconsin facility, creating better working conditions for employees and significantly increasing productivity of their palletizing process.