Case Studies

Assa Abloy

Close the skills gap with in-house robotics expertise

20%

Increase in productivity

20 s

Cycle time

10

New employees hired in the automation department

About Assa Abloy

Assa Abloy’s offerings include products and services related to locks, doors, gates, and entrance automation. Related products and services include controlling access and confirming identities with keys, cards, tags, mobile, and biometric identity verification systems.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Watch how Assa Abloy leveraged automation: Overcoming a skills gap with the Machine tending solution

Factories don’t buy a robot to replace people, they buy it because they cannot find people. I’ve never seen someone in Romania lose his job to a robot.

Razvan Isac

Sales Manager, RobotsNET

Overcoming Challenges: Our Solutions

The Problem

Assa Abloy Romania assembles locks, which are then sent to other Assa Abloy factories worldwide, where they’re transformed into finished products. The factory suffered from a huge skills gap in Bucharest, the country’s capital city, where the unemployment rate is low. Difficulties in attracting new workers to manufacturing forced an automation revolution.

The Solution

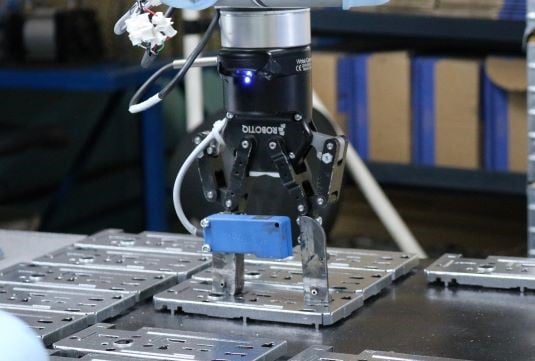

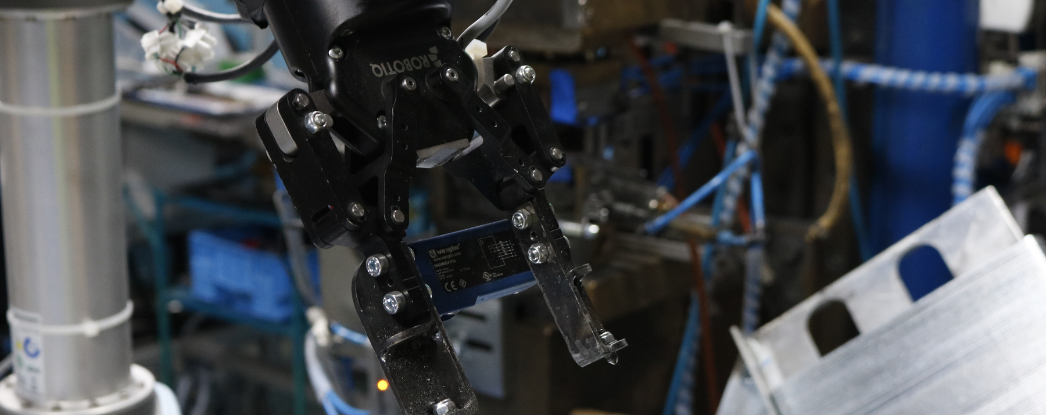

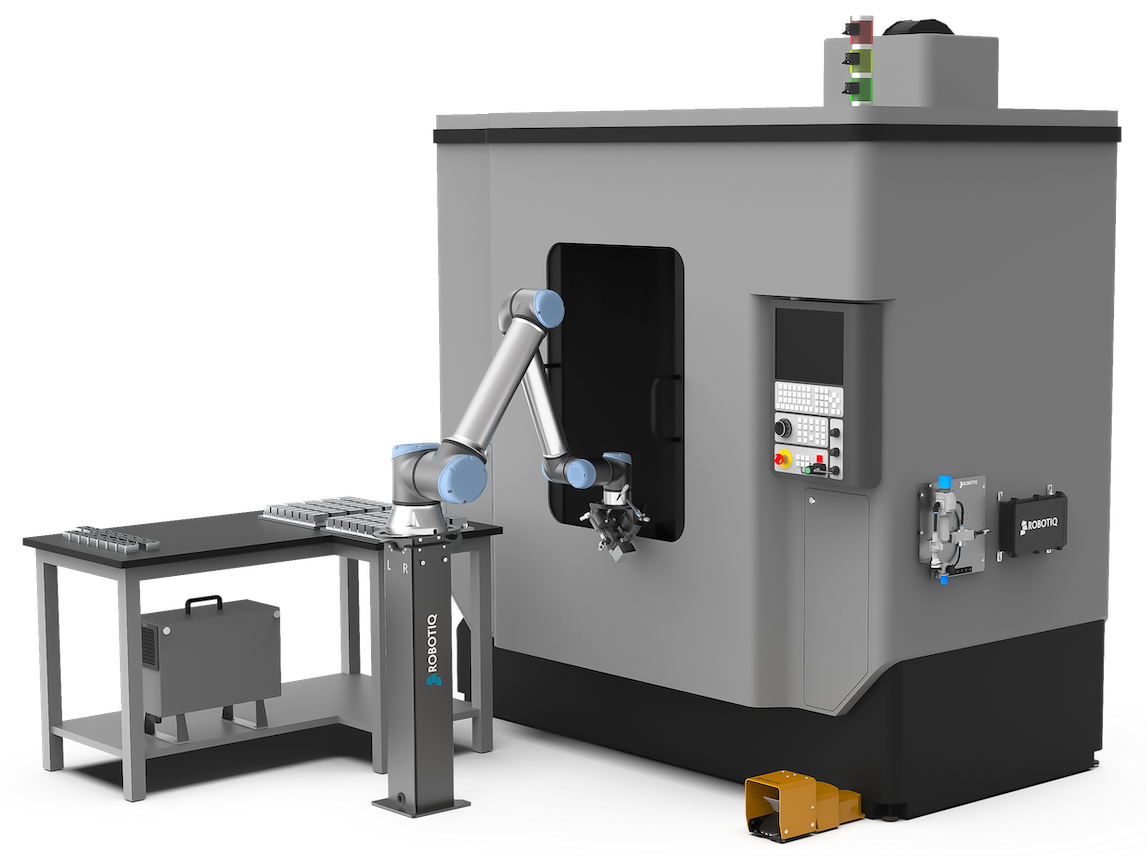

In-house robotics expertise was built around a group of engineers and technicians in charge of automating processes with new technologies. The team chose the Robotiq 2-Finger Adaptive Gripper and Wrist Camera to pair a Universal Robots UR5 for a machine tending process. Two parts are positioned by the robot on a fixture and then welded by the machine.

The Results

Lean robotics at their best.

Robotiq’s Machine Tending Solution brought benefits on many levels:

- Design: Robotiq 2F-140 Adaptive Grippers allowed to program different positions and tailor them perfectly for each part of the process.

- Integrate: The integration took less than a week. Most employees didn’t know anything about robots. They spent a few hours learning how to program, how to make the grippers work, and how the machines had to work.

- Operate: Now their machines run full-time and production capacity has doubled.

The Robotiq solution

In-house robotics expertise was built around a group of engineers and technicians in charge of automating processes with new technologies.

Applications

Machine Tending

Robotiq’s Machine Tending Solution offered Assa Abloy the opportunity to automate their welding process, including locating the front plate, placing it in the welding machine, picking the case and placing it correctly over the plate on the fixture.