-1.jpeg?width=2000&name=2F85-Wrist-Camera-Machine-Tending-Walt-Machine-58%20(1)-1.jpeg)

Case Studies

Walt Machine

The evolution of a machine shop

2500%

Production increase

3

CNCs

3

CNCs

About Walt Machine

Walt Machine makes precision aluminum parts for optical assemblies—their specialty—and offers other manufacturing services.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Leveraging cobots to deliver 6000 camera housings in 2 months’ time, with only one CNC machine.

We went from making about 1,000, 1,500, or 2,000 parts at a time, to about 45,000-50,000 of these parts.

Tommy Caughey

President, Walt Machine

Overcoming Challenges: Our Solutions

The Problem

Since our last case study with WALT Machine Inc., they have seen a huge increase in demand, but hiring new employees hasn’t gotten any easier. Tommy Caughey, president of WALT Machine Inc. has already succeeded with automating a first CNC machine. He is now looking to scale its production and automation capabilities to meet growing customer needs.The Solution

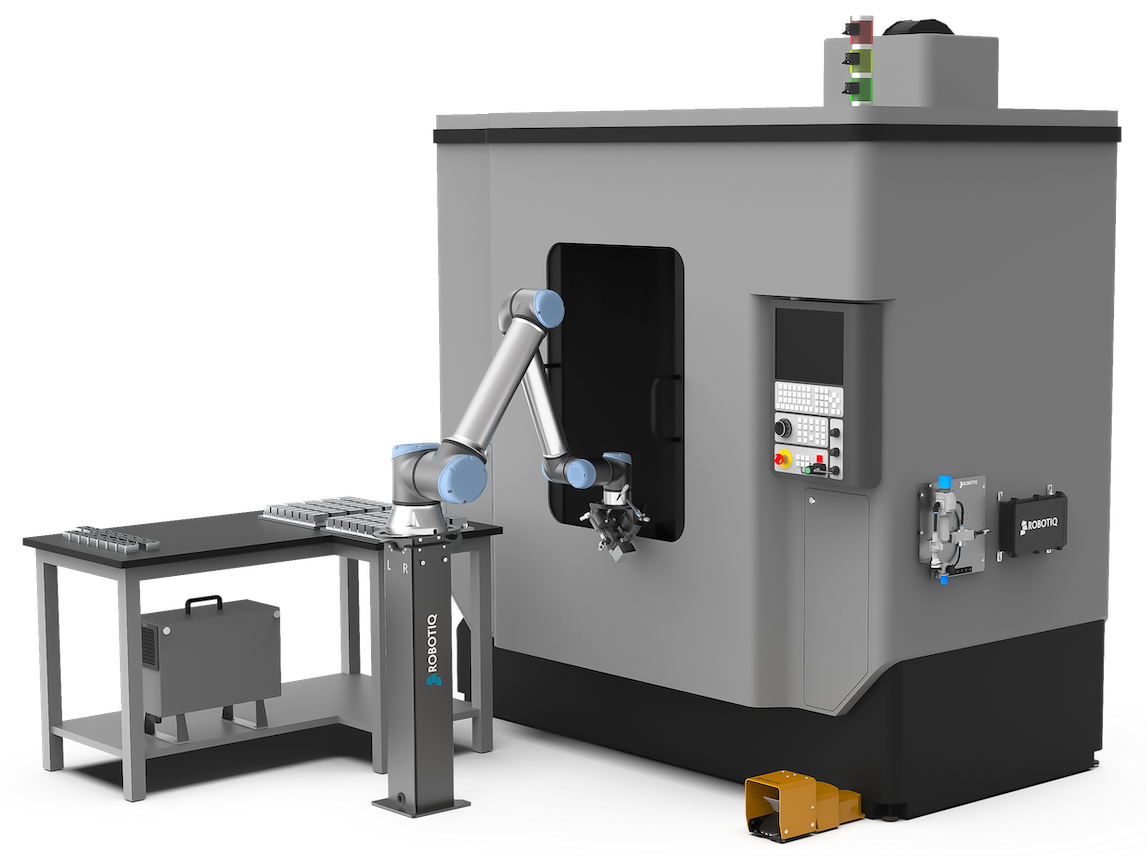

Caughey already had part of the answer with his first application. He started small instead of trying to automate everything at once. It worked: his Robotiq 2F-140 Gripper, installed on a ceiling-mounted Universal Robot UR10, is tending three different machines. He’s now installing a Robotiq CNC Machine Tending Kit on a new UR and automating a second application.

The Results

Increased productivity

Robotiq Machine Tending Solution helped increase productivity and consistency:

- Productivity: The results speak for themselves. Whereas one robot doubled daily production, two robots have let them increase production by 2,500%.

- Dealing with a small footprint: As Walt Machine was dealing with a very small footprint, the robots were installed on a rail to the ceiling of the facility.

The Robotiq solution

Walt Machine installed a Robotiq 2-Finger 140 Gripper on a UR10 cobot to tend CNC machines around the clock, which doubled daily production.

.jpg)

Applications

Machine Tending

Walt Machine initially installed a Robotiq Wrist Camera and 2-Finger 140 Gripper on a UR10 cobot to tend CNC machines around the clock, which doubled daily production. Since then, they’ve added two more robots and scaled up from making 2,000 parts to 50,000 parts.