Case Studies

Alliora

How a box manufacturer tackled labor issues by automating palletizing tasks

23

Metric tons: The approximate amount of weight a worker moves per shift.

1

Week: To go from receiving the solution to stacking boxes

18 months

ROI

About Alliora

Alliora is located in Fougères, a small town in the Brittany region of northwestern France, where it manufactures boxes for a wide range of clients in industries like board games, cosmetics, and champagne. Alliora had wanted to add automation to its production lines for a while. Unfortunately, their first experience was difficult. Industrial robots were too complex. They bought one, but they were never able to get it to work properly. Meanwhile, the need for automation remained as they were forced to hire many temporary workers to meet seasonal demand. In collaboration with Sterkelec, Robotiq’s local partner, they targeted the end-of-line and implemented the Robotiq collaborative robot Palletizing Solution. Employees are grateful, and the production line is flowing better than ever.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Overcoming Challenges: Our Solutions

The Problem

Alliora specializes in creating and manufacturing high-end packaging. Being a seasonal business, they hire many temporary workers when orders come in. They needed a way to stabilize production so they could reduce the number of temporary workers and help their core group of employees with strenuous stacking tasks.The Solution

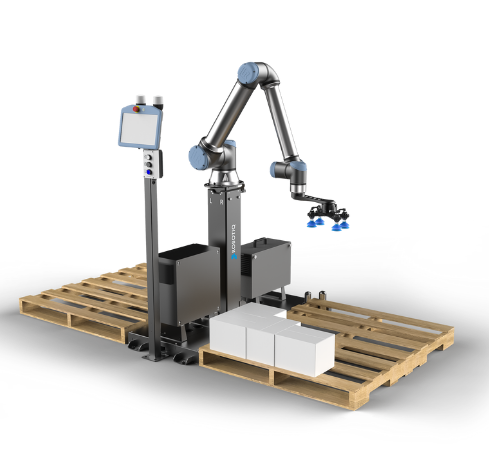

After a few hours of research, they contacted Sterkelec, a Robotiq local partner. Together they targeted the end-of-line and implemented the AX Series Palletizing Solution from Robotiq. Employees are grateful, and the production line is now flowing better.

A fast ROI

Robotiq Palletizing Solution helps stabilize the production line:

- Productivity: The cobot’s presence allows Alliora to hire two fewer temporary workers during high production periods, which helps stabilize the production line.

- ROI: Alliora estimates the ROI at 18 months, which is fast. It’s a successful experience they plan to replicate soon—the goal being to add a Robotiq Palletizing Solution on three or four more production lines.

The Robotiq solution

-1.jpeg)

Palletizing

Efficient palletizing is crucial for connecting products to customers. Given industry challenges like high turnover and labor shortages, depending on humans for repetitive tasks like palletizing is increasingly impractical.

The Robotiq Palletizing Solution, more than just a cobot, swiftly adapts to your operations, ensuring efficient, consistent demand fulfillment with minimal downtime. Its user-friendly software simplifies the process, preparing your business for current and future challenges.