Case Studies

Usinatech

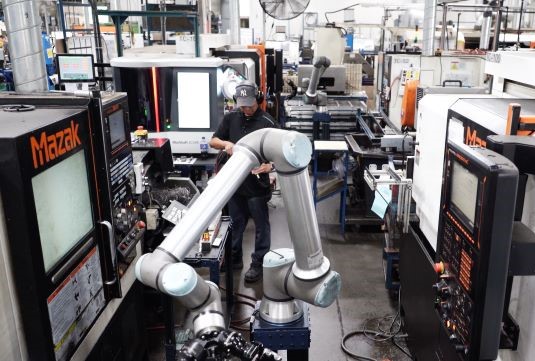

The art of implementing cobots on a busy production floor

3 CNCs

The number of stations an operator can manage simultaneously (instead of just one).

6 Robotiq Machine Tending Kits

To help face a labor shortage and increase operator productivity

50%

Lower implementation cost than industrial robots

About Usinatech

Located in Melbourne, Quebec, Usinatech has been making critical drivetrain and transmission components, like gears and shafts, since 1986. They employ 300 people in Canada and 50 more in Mexico. Usinatech has been automating its production cells for many years. However, the growing labor shortage and the need to become even more competitive in the market have forced Usinatech to accelerate its shift to automation.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Usinatech: The art of implementing cobots on a busy production floor

What Robotiq’s grippers have to offer is a step beyond any of the competitors.

Vincent Roussy

Manufacturing Engineering Manager

Overcoming Challenges: Our Solutions

The Problem

Since 2017, the growing labor shortage and the need to become even more competitive in the market have created a lot of pressure on the manufacturing floor. According to Usinatech, automation was the way to go!The Solution

Usinatech accelerated its shift to automation. Patrick Coté and Vincent Roussy are glad to say this shift has resulted in significant productivity gains, lower operating costs, and a lower employee turnover rate, which has stabilized all aspects of production and distribution.

The Results

Effective ROI.

Robotiq’s Machine Tending Solution brought benefits on many levels:

- User-friendly: Usinatech integrated the first three cobots by themselves. Once tested and standardized, the process became so simple and efficient that cobot implementations are now an internship project for college students.

- ROI: The total project cost for implementing a cobot at Usinatech is at least 50% lower than for an industrial robot.

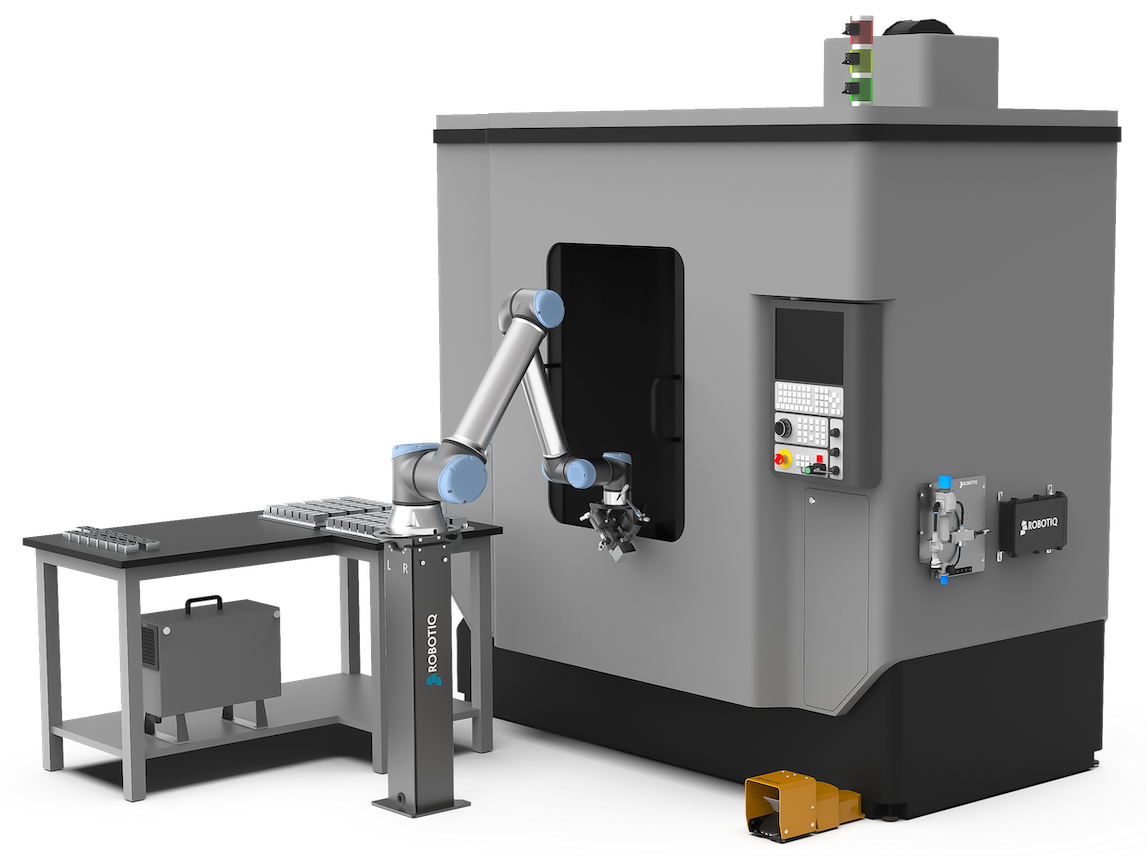

The Robotiq solution

Usinatech’s decision to automate cells using both Robotiq’s collaborative robots and insights from lean robotics has led to a faster ROI

Applications

Machine Tending

Usinatech’s decision to automate cells using both the Robotiq Machine Tending Solution and insights from lean robotics has led to a faster ROI.