.jpg?width=2000&name=Zago%20Insights%20Force%20Copilot-10%20(2).jpg)

Case Studies

Zago

Increase capacity with automated night shifts

24/7

Automated production

100%

Automated application

½ day

Saved for each minor tweak

About ZAGO

ZAGO Manufacturing is a family-owned business based in New Jersey. They produce custom, high-tech and green sealing solutions and components. ZAGO’s sustainable sealing solutions and components are used in various industries, including aerospace, automotive and transportation, commercial LED lighting, medicine, robotics and drones, energy and electronics.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Zago Increased Capacity with Automated Night Shifts

Now the operator is inspecting parts coming out of the machine and programming the robot instead of operating the machine

Jackie Luciano

Vice-President, ZAGO Manufacturing

Overcoming Challenges: Our Solutions

The Problem

ZAGO Manufacturing faced an increase in customer demand for high-tech sealing fasteners and switch seals. With limited workers available in the New Jersey area, ZAGO’s management looked for a cost-effective and robust automated solution.The Solution

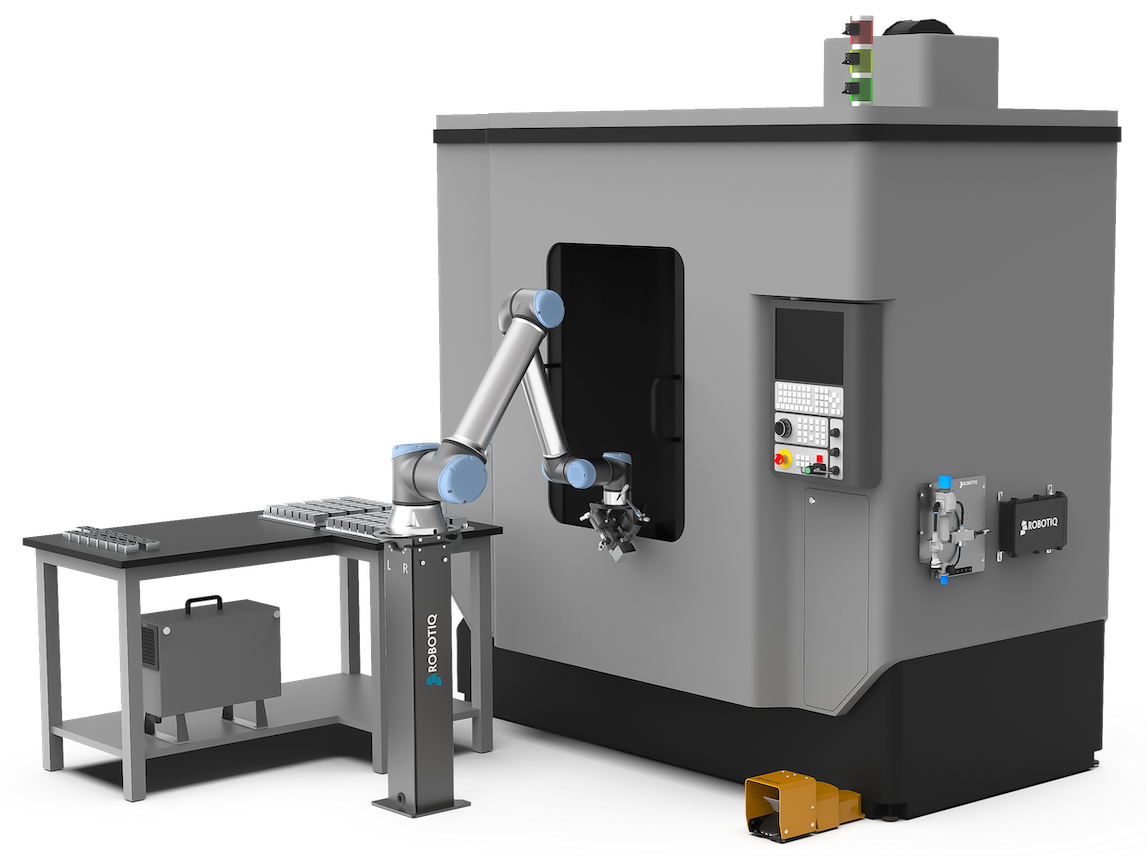

A Universal Robots UR10e cobot arm equipped with Robotiq software proved to be the perfect fit for their needs. Since ZAGO manufactures precision parts for the aerospace industry, they appreciate how Robotiq’s Force Copilot ensures that the UR10e places each part precisely into the chuck..jpg?width=535&height=361&name=Zago%20Insights%20Force%20Copilot-7%20(1).jpg)

The Results

Lean robotics at their best.

Robotiq’s Machine Tending Solution brought benefits on many levels:

- Design: ZAGO focused on applications that were automatable and that resulted in a lot of downtime.

- Integrate: The synchronization with the CNC machine was machine, resulting in a 100% automated machine tending application.

- Operate: The robot cell was made completely reliable for the unattended night shifts.

The Robotiq solution

A Universal Robots UR10e cobot arm equipped with Robotiq software proved to be the perfect fit for their needs of precision

Applications

Machine Tending

The Robotiq Machine Tending Solution helped ZAGO in automating precision parts production. This automation allowed them to answer to the ever-growing demand of their customers.