-1.jpg?width=2000&name=palletizing_last_box_almost%20(2)-1.jpg)

Case Studies

Napco

Growing family business keeps the coffee flowing with affordable, easy-to-use cobot palletizers

1 day

Installation and training

180 000

Coffee cups packed daily

12 mo

Return on investment

About Napco

Napco Brands has been serving the Chicago area since the early 1900s. The company has been a beacon of quality coffee for consumers at home. Over the years, Napco Brands has evolved from producing a single in-house brand to managing four distinct brands. Eric Latsch, the VP of operations for Napco Brands, highlighted their extensive capabilities, ranging from roasting to packaging for retail and food service businesses. The company’s commitment to quality and innovation has made it a recognized name in the coffee industry, and its move towards automation with cobot palletizers further underscores its dedication to modernization and efficiency.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Napco Brands: 15% throughput increase using UR robots and Robotiq Palletizing Solutions

Having this automation with a higher efficiency has made it possible for us to acquire new customers. We have several new private-label customers that we couldn't have dreamed of two years ago.

Erich Latsch

Manager, Napco

The Problem

Napco Brands has a lot of capability to pack coffee beans for private labels. However, finding enough workers to support the private label integration has been a challenge.The Solution

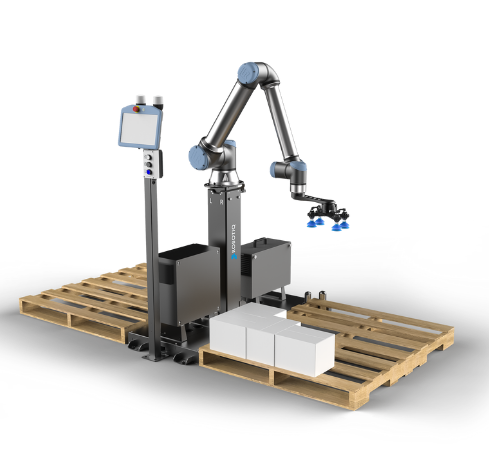

To support business development and address labor shortages, the company installed two automated palletizing solutions from Robotiq featuring the UR10e collaborative robots (cobots) from Universal Robots (UR). They freed up eight workers for more valuable tasks.

The Results

Convincing wins.

Robotiq’s palletizing cobot brought benefits on many levels:

- Business growth: Robotiq Palletizing Solution due to its ease of deployment, its ability to handle a wide variety of pallet heights, helped Napco to grow in a tight labor market.

- Performance: The cobot palletizers run two shifts, operating 18 to 20 hours per day, and palletizing cell fills 1,500 boxes, totaling 180,000 single-serve coffee cups packed daily.

- Eight operators freed up: Rather than performing manual labor tasks like palletizing, those employees have been redeployed to operate bigger equipment at higher pay in specialized tasks.

The Robotiq solution

Robotiq Palletizing Solution transformed Napco’s operations, leading to a 15% increase in production.

Applications

Palletizing

The Robotiq Palletizing solution transformed Napco’s operations: not only did it lead to a 15% increase in production, but it also reduced the risk of injuries and allowed the company to reallocate eight workers per day to more specialized tasks.