Increasing output by 50% without adding floor space sounds unrealistic for most manufacturers. That...

ROBOTIQ

Lean Palletizing

Start fast. Scale with confidence.

Automation made easy with Lean Palletizing

Your end-of-line is the final stop before delivery to your customers. It's also one of the most manual and labor-intensive. Manual palletizing is hard to staff and harder to scale. Robotiq helps you automate it—without complexity, long timelines, or rigid systems.

Lean Palletizing is fast to set up, easy to use, and ready to scale with your business.

It’s everything you need, nothing you don’t.

Empower people

Remove repetitive tasks and reduce strain.

Boost productivity

Easy to set up. Easy to use. No robotics experience needed.

Predictable payback in 1-2 years.

Enhance adaptability

Handle new SKUs, pallet patterns, and setups with ease.

Structured decision-making process with practical tools to assist you in making a smart choice.

Lean Palletizing Experience

From online validation and design to your end-of-line productivity.

1. Select

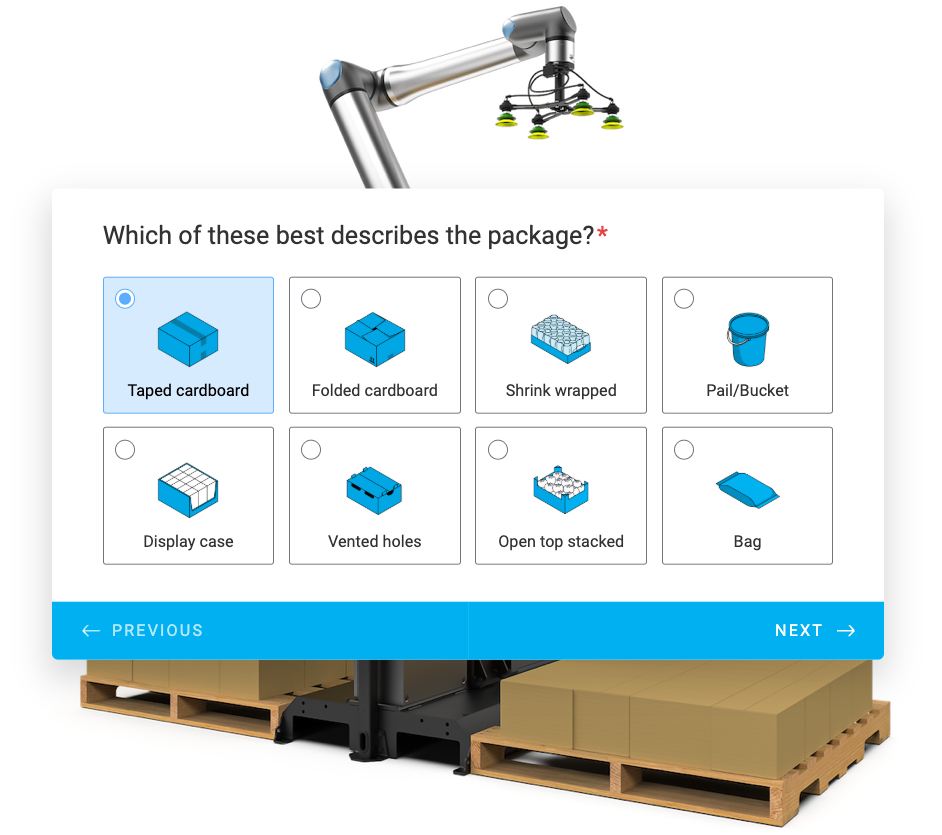

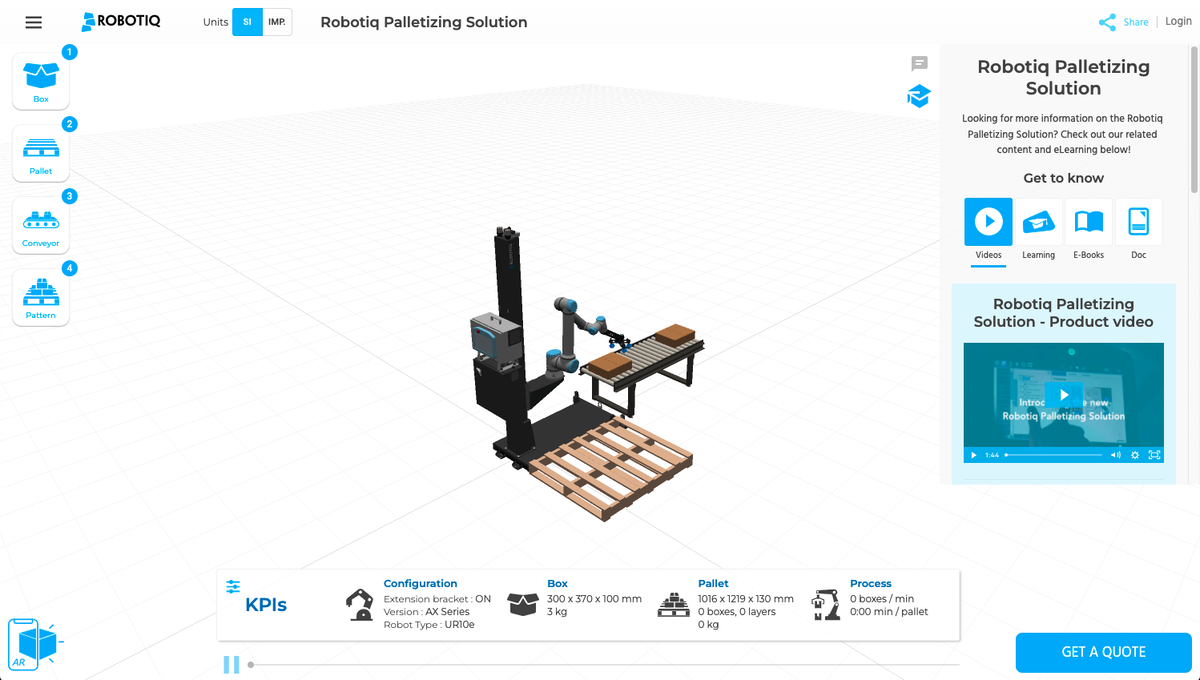

Select the right palletizing station and confirm feasibility with our Palletizing Fit Tool. In a matter of minutes, you'll know which setup works best for you. You'll also receive:

A 3D simulation tailored to your factory requirements

A detailed ROI, price range and payback period calculation

A comprehensive report you can share with your team

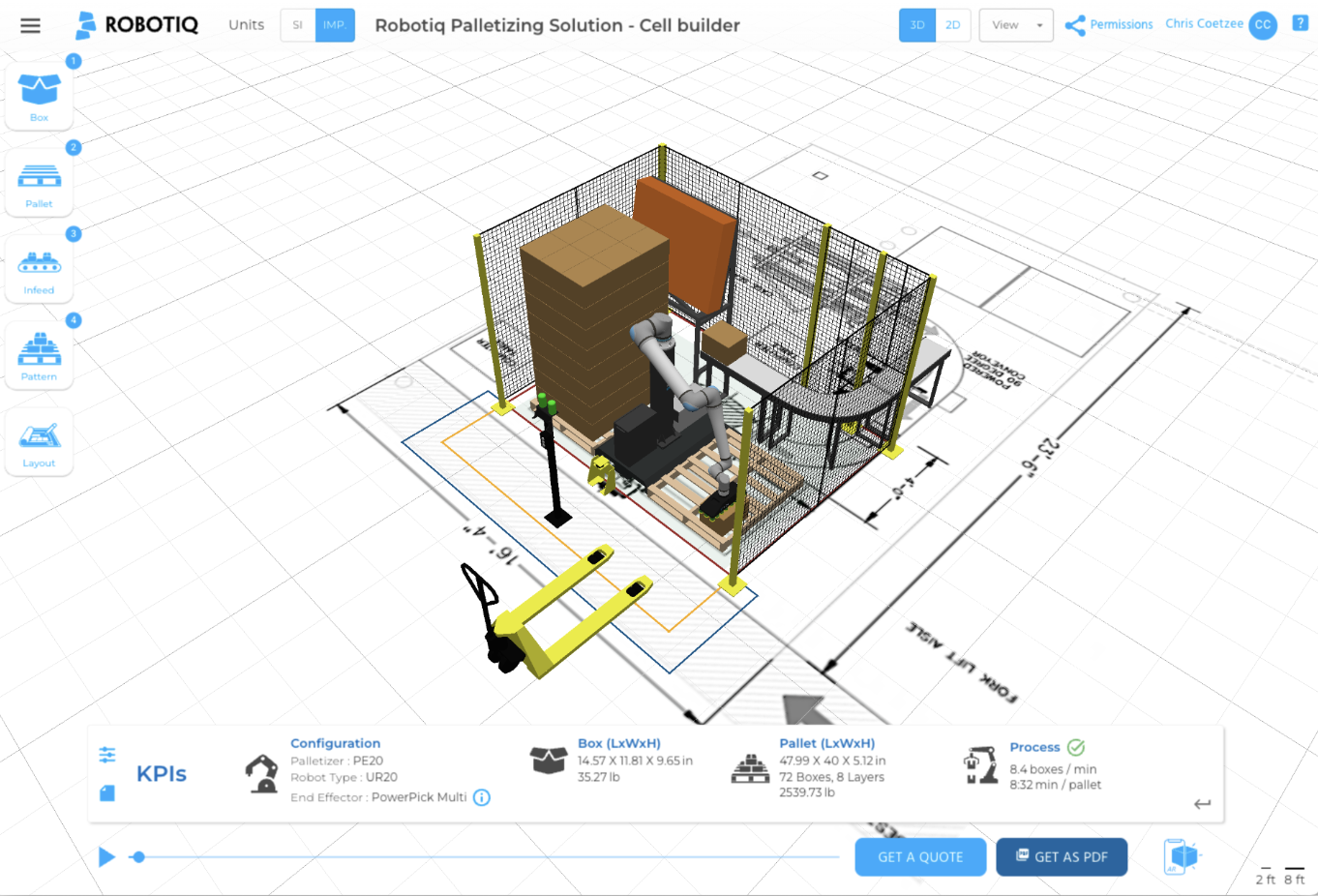

2. Simulate

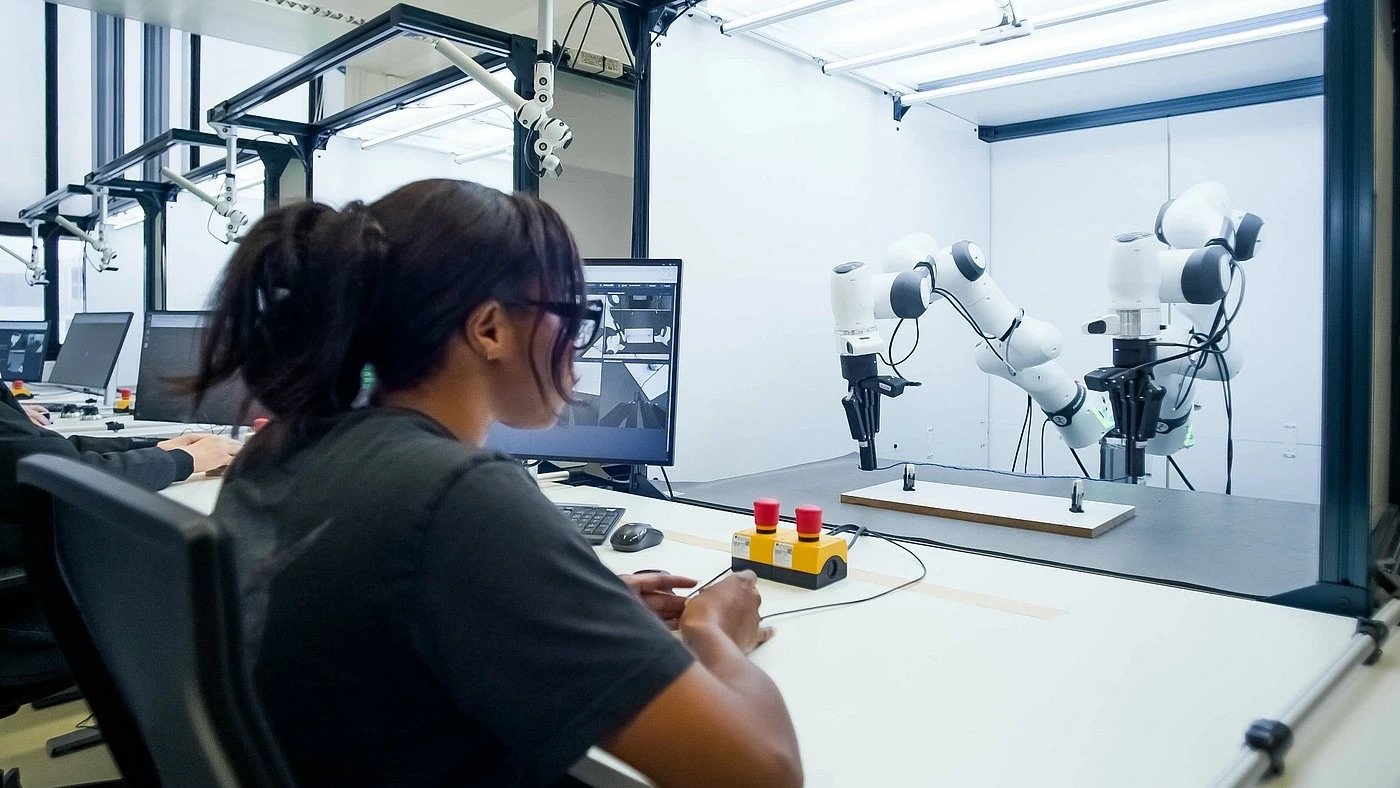

Watch your palletizing cell come to life! Collaborate in our online Configurator to simulate real operations on your floor layout.

3. See

Our partner network is spread across the globe. There is bound to be one near you!

Get a hands-on look with your own products. See a PAL in action at your local Robotiq Expert Partner facility.

4. Start

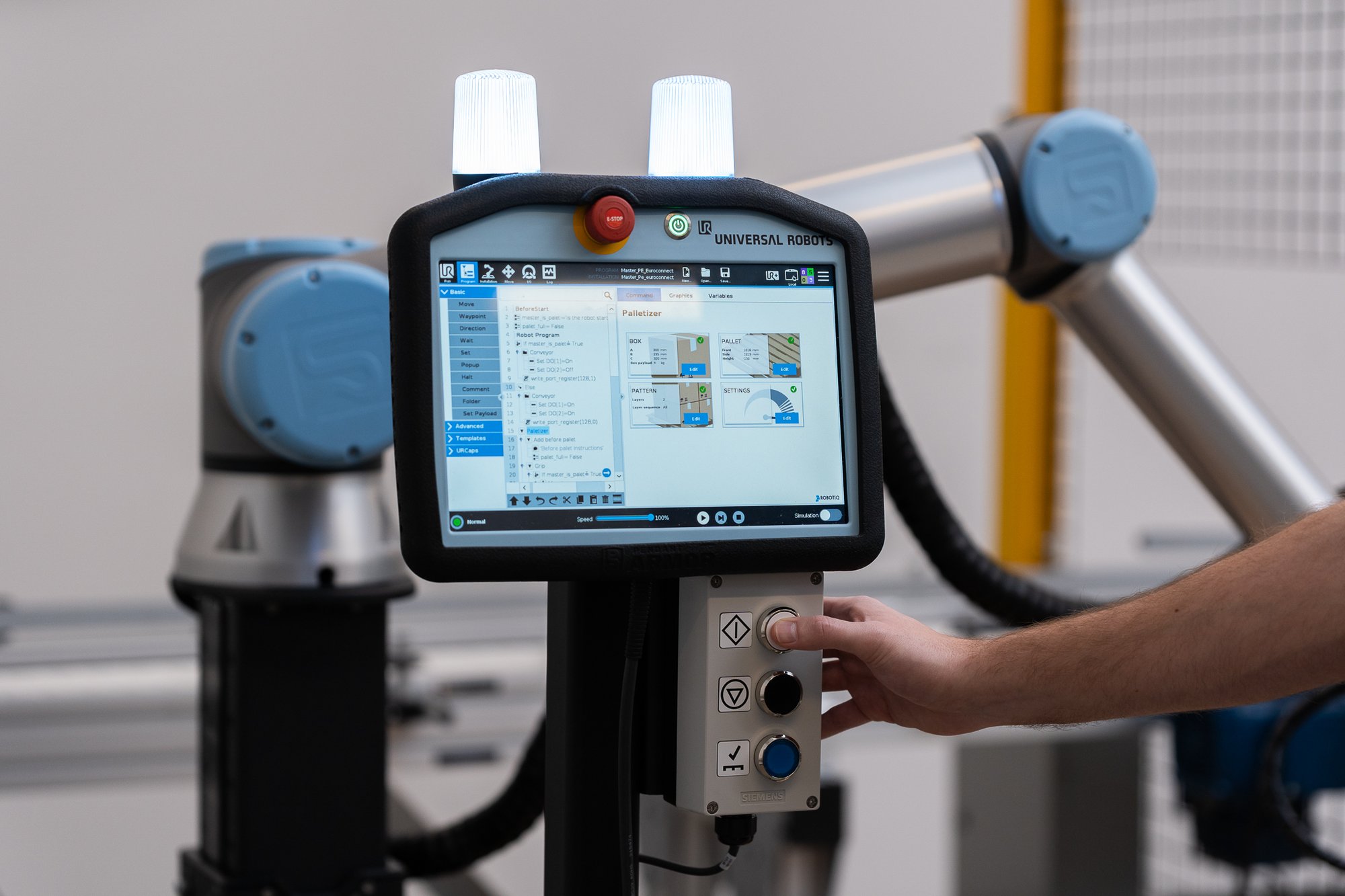

Launch into production with easy-to-use PAL software, plus the support and training you need.

5. Scale

Expand PAL deployments to your other lines to accelerate ROI and boost productivity.

.jpg?width=1779&height=1000&name=Robotiq%20Background%20(Cascade%20Coffee).jpg)

What's included in Lean Palletizing?

With Lean Palletizing, you get the palletizer that fits your operation best: PAL Ready or PAL Series.

Both options allow you to start fast, scale with confidence, and get:

- The same intuitive software and operator experience

- The same digital tools and deployment confidence

- The same Lean Robotics design principles

- The same global partner network and support

Production-ready palletizer

A fully assembled, robotic palletizing cell, designed for rapid installs.

Modular palletizers

A configurable palletizing option built from Robotiq standard models PE/AX Series and modules, supported by certified partners or Robotiq Installation Services.

PAL Ready

Get started fast and easy

Production-ready to skip project design and validation steps for faster deployment.

Fast and predictable ROI

Reduced delays, no production stop, no extra engineering required.

Confidence to grow

Scale ROI across lines and factories with one seamless operator experience, powered by PAL Ready and PAL Series.

PAL Ready

Smooth transition from your upstream conveyor, automatically delivering boxes at the right time and the right place.

Flexible gripper with no changeovers between products.

PAL Ready

Anchorless redeployment in under 10 minutes:

- Enable multiple production lines with low-volume production

- Support washdown zoning for food & bev

- Empower any team member - no tools, no forklifts or engineering support required.

PAL Ready

Work made easier and safer for your operators.

Robotiq puts the operator experience first:

Flexible and robust software – Easy to learn and intuitive to use, so operators get productive fast.

Safety package – Keeps the cell open and accessible, ensuring a safe workspace without bulky fences.

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

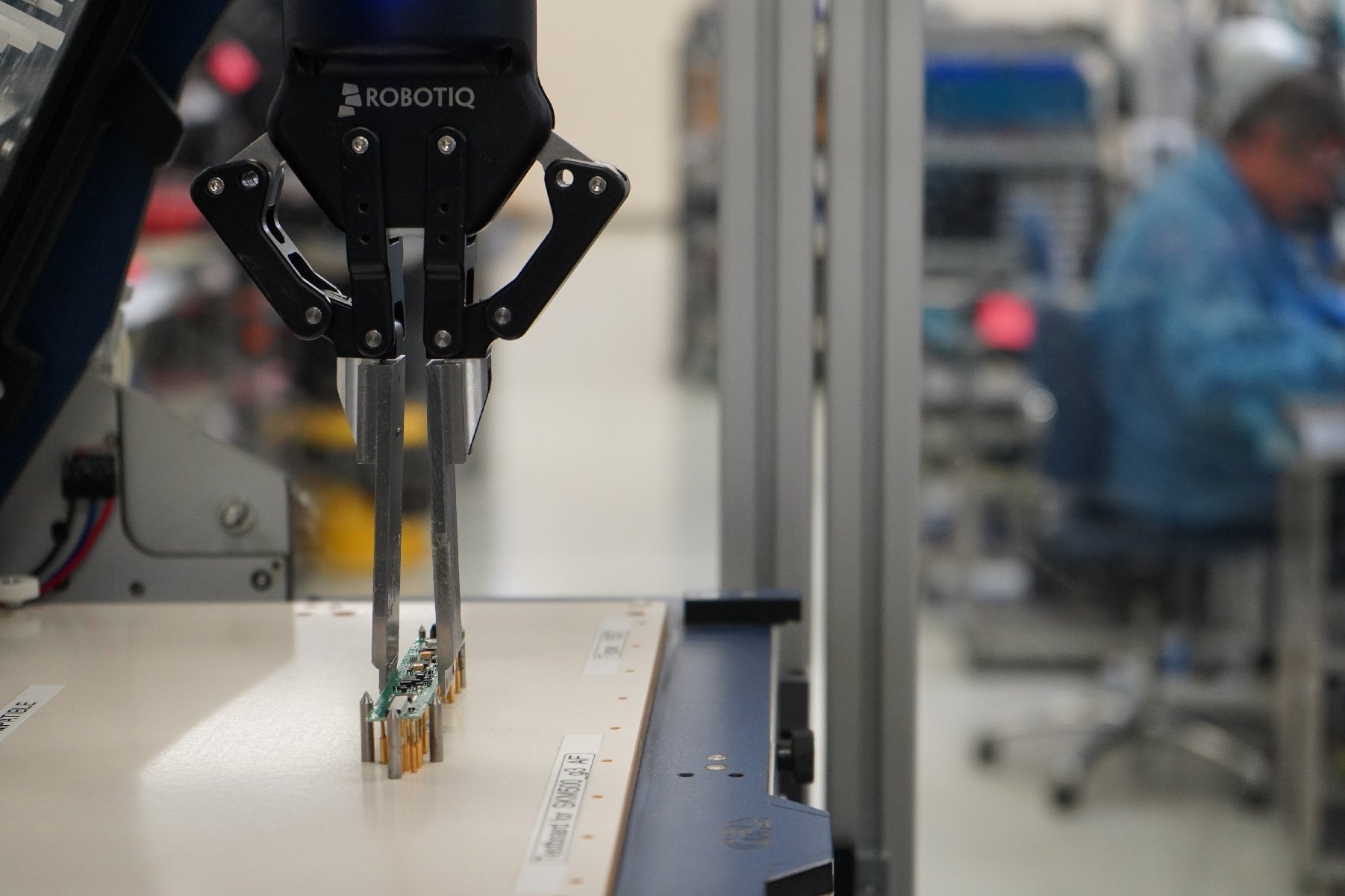

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

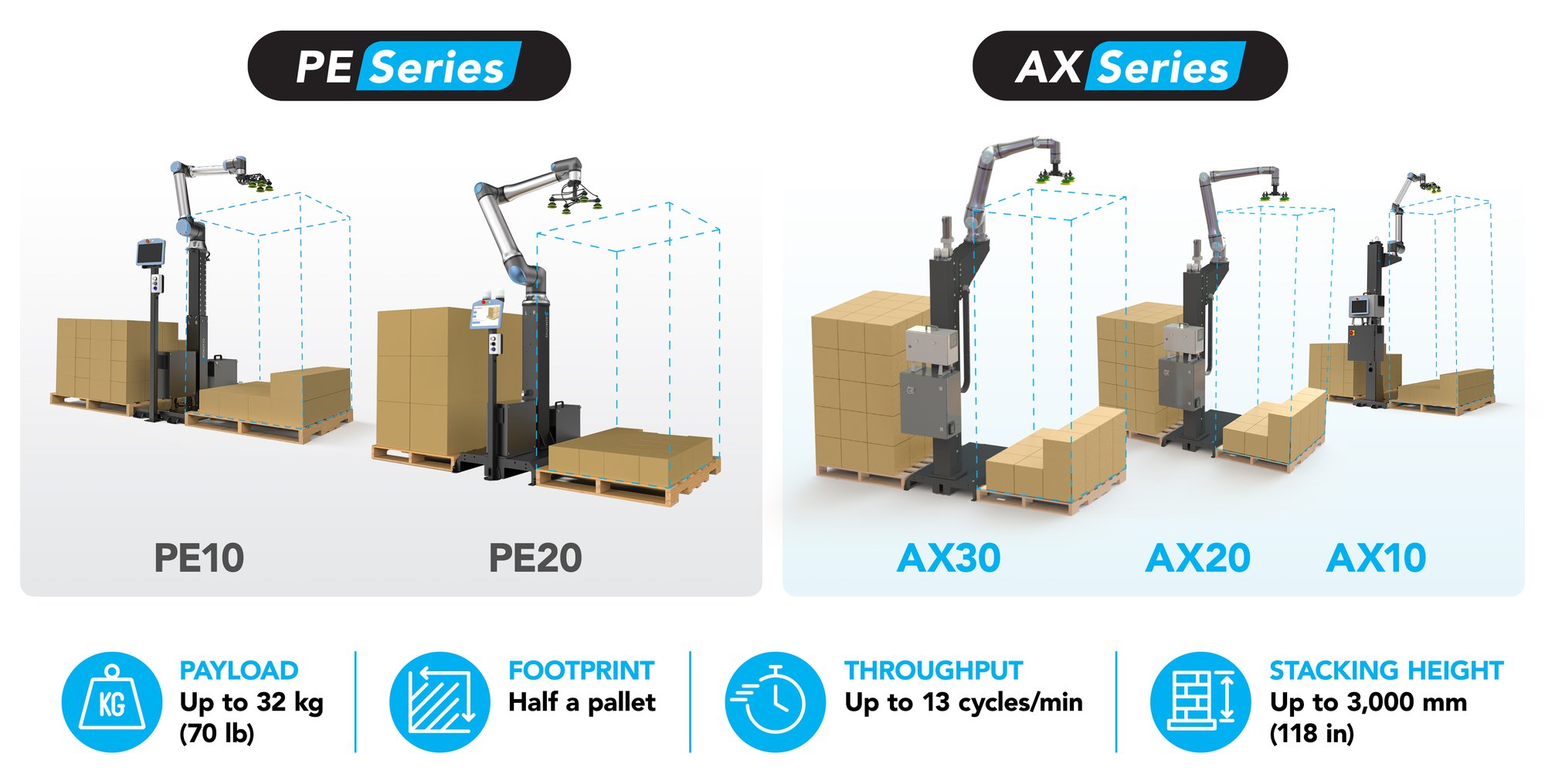

PE Series / AX Series

The PE Series is ideal for facilities with fewer pallet height variations. By mounting cobots on a pedestal, it maximizes floor space while delivering reliable performance in compact areas.

The AX Series uses a 7th axis as a linear transfer system to extend the robot’s vertical reach. It offers the fastest cycle times and the greatest reach of any comparable palletizing system — all within a compact footprint.Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) -

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

Smart Infeed

- Right place, right time. Automatically present any box to the palletizer for optimal output with almost no programming.

- No more bottlenecks. Eliminate downtime from manual handling and keep productivity high with an automated SKU infeed.

- Always in flow. Integrated recovery logic manages box pressure and ensures seamless transitions.

- Fast to deploy. Out-of-the-box and communication-ready, Smart Infeed cuts lead times and gets you palletizing sooner.

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) -

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

Vacuum Grippers

The PowerPick vacuum gripper line is designed to handle a wide range of applications, with a key focus on maximizing lifting capacity, productivity, and adaptability, making the grippers preferred choices to perform heavy-duty tasks like palletizing.

PowerPick Multi elevates your palletizing solution by eliminating gripper changeovers and manual handling. Its flexible cup array, dual-zone picking, and intuitive URCap integration make it easy to adapt to any box size and future production changes.

Equipped with a vacuum generator that attaches to the base of the robot, the PowerPick 10-20-30 set a new standard for lightweight and enhanced lifting performance in their category.

Learn more about our Vacuum Grippers. -

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

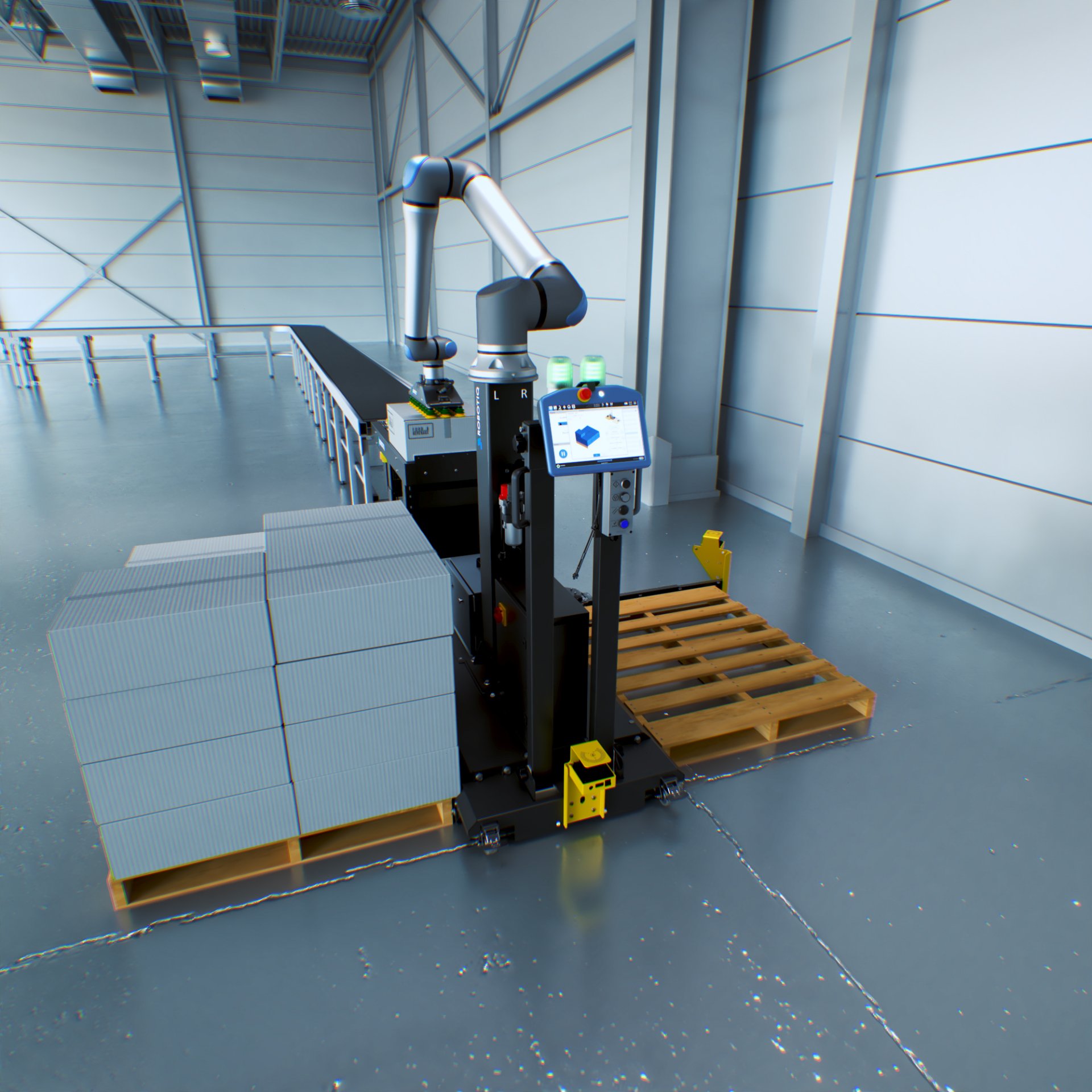

PE20 Mobility Kit

Mobile Operation

Designed to palletize on intermittent lines and ensures clearing of area for full washdown compliance or any other regulations.

Anchorless Flexibility

No need for floor drilling. The anchorless design lets you adapt your layout anytime without permanent modifications.

Zero Downtime Integration

Keep production flowing: assemble, test and roll into production.

Effortless Mobility

Move it like a pallet jack, no tools required.Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) Stroke 50 mm (2.0 in) 50 mm (2.0 in) 50 mm (2.0 in) -

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

Safety Packages

Maximize your palletizer’s performance with confidence while maintaining a safe, compact work environment.

Robotiq Safety Packages are modular, easy-to-integrate add-ons designed to keep your palletizing cell safe during high payloads, tall stacks, faster cobot speeds, and other scenarios identified in your risk assessment.

-

✅ Keep it open: No need for bulky fences during pallet changes

-

✅ Save space: Maintain a compact footprint on your factory floor

-

✅ Boost performance, safely: Get the most from your palletizing solution while ensuring operator safety

-

6500

Cases palletized in a day

6500

Cases palletized in a day

6500

Cases palletized in a day

Applications

Versatile Applications of Hand-E Grippers by Robotiq

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Quality Testing

Read more

Features

Key Features of Hand-E Gripper by Robotiq

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Integration

Easy to integrate, easy to use

Robotiq’s Hand-E Gripper is simple to integrate in your production environment and easy for workers of all skill levels to use—no robotics experience required.Install your adaptive gripper in just a few minutes, thanks to our Plug + Play gripper kits. Then use our intuitive software interface to program directly on your robot’s touchscreen.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Accelerate your production line

Increase productivity and improve your cycle time with a dual configuration, which lets you handle more objects at a time. The dual Hand-E configuration is the perfect way to keep your CNC machine fed, even when your operators are away.

Technical Documentation

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

Robotiq has a variety of technical information available for your solution.

Specifications

Morem ipsum dolor sit amet

Qorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) Stroke 50 mm (2.0 in) *Calculated for the use of silicon covered fingertips to grip a steel object, at a low robot acceleration.

Customers stories

Gorem ipsum dolor sit amet, consectetur adipiscing elit.

See how the 2-Finger Adaptive Robot Gripper helped triple Voodoo Manufacturing's 3D printing production

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

Interlayer (Slipsheet) Feeding System

The Interlayer Feeding System streamlines the handling of rigid cardboard slipsheets, making it easy to integrate interlayer placement into your automated palletizing workflow.

-

Adaptable by design. Handles different interlayer sizes with minimal downtime.

-

Seamlessly integrated. Comes with all programming needed to add interlayer placement into your pallet recipes.

-

Consistent & reliable. Ensures smooth performance and stronger pallet stability, every time.

A simple, smart add-on to strengthen your palletizing solution.

Robotiq Lean Palletizing software

Simple where it matters, powerful where it counts. Experience software that empowers people, boosts performance, and grows your business.

-

For operators: Select a recipe, start, palletize. Fewer steps, fewer errors, and a day that’s predictable and productive.

-

For technicians: Full autonomy. Quickly add new SKU and adapt to production changes while keeping palletizing consistent and flexible.

- For the business: Reliable, robust and designed to evolve with your business with AI-based optimized trajectories, smart handling of variability and scalable open platform.

Small footprint

Installs in 3 days. Fits your space. Scales with you.

No need to reconfigure your line or halt production.

Robotiq’s compact system fits your layout now and grows with it later.

How much does it cost?

The exact cost depends on your factory’s setup, but the payoff is clear—most factories see ROI in 1–2 years through labor savings, higher output, and lower hiring costs.

Want real numbers for your operation? Answer a few questions through our Palletizing Fit Tool to get a detailed ROI, price range and payback period calculation.

Ready to move forward?

Who's using it?

Key result: 13-month payback

"So really it's a very quick, fast, simple solution, and it's one that can be rolled out at pace across multiple lines within a factory."

- Ken Maguire

Managing Director, Glenhaven Foods

Key result: 5 million bottles handled per year

"The cobot perfectly reflects what we need. It is a flexible machine, compact, quick to set up, and, ultimately, affordable. We were able to automate a task that was extremely tedious. No one complains about back pain anymore. At least not from palletizing."

- Sebastian Raumland

Managing Director, Raumland GmbH

"The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years."

- Greg Thayer

Vice-President, Cascade Coffee

"The key result for our production process is that we are now further flexible in our processes and product planning, and we decreased the hard work of our employees."

- Simon Gunnemann

Managing director central production, Hack AG

FAQ

What's a cobot?

A cobot (collaborative robot) works safely alongside people, boosting productivity without barriers. Built with advanced sensors and smart programming, it adapts to human interaction—no cages, no complexity.

What robot do you use?

We use industry-leading Universal Robots in all of our palletizing solutions for their reliability, ease of use, and seamless integration. They’re built for flexibility, safety, and fast deployment—so you get up and running in no time.

How safe is it?

Cobot palletizing doesn’t just meet safety standards—it improves workplace safety. Manual palletizing leads to fatigue and injury from repetitive lifting and awkward postures. Automating with cobots eliminates these risks while built-in safety features like force detection, collision prevention, and controlled speeds keep operations secure.

For more information, download our ergonomics ebook

How is it different from other solutions?

Unlike centralized solutions or industrial palletizers that require extensive conveyor rerouting and reduce operational flexibility, our cobot palletizing solutions keep your lines flexible and resilient. Designed for Lean Robotics, they integrate seamlessly into existing layouts—no extensive modifications needed.

Our advanced control algorithms and tooling deliver higher throughput than other cobot solutions. Unlike rigid "in-a-box" systems, Robotiq’s palletizer scales with you, integrating additional automation as your needs evolve.

And while custom-engineered palletizers require long design cycles, ours offers short lead times and intuitive software, making it easy to add new products or pallet patterns. For more information see our Automated Palletizing Buyer’s Guide.

Where can I see it in action?

Our global network of Expert Partners is available to show you a demo. You can even test a Robotiq Palletizing Solution with your own products if you wish! Book a demo with an Expert Partner near you.

The Robotiq team also travels regularly to trade shows to give live demos of the Robotiq Palletizing Solution. Check out our events page to see if we'll be in your area soon!

What is Lean Robotics?

Lean Robotics is a methodology for simplifying robotic cell deployments. It is a systematic way to complete the robotic cell deployment cycle, from design to integration and operation.

The Lean Robotics book by Robotiq CEO Samuel Bouchard is the result of a decade of the company’s experience helping thousands of manufacturers overcome production challenges using robots.

Resources

Ready when you are!

See what fits best

Want to see if a Robotiq Palletizer fits your operation? Answer a few questions and we'll show you which setup works best for you along with a ROI calculation, price range and 3D simulation

-2.png)

1_2026_Siemens_UR_demo_CES2026.gif)

.png?width=1920&height=1080&name=Untitled%20design%20(12).png)

.png?width=1920&height=1080&name=Untitled%20design%20(11).png)