Case Studies

Biolintec

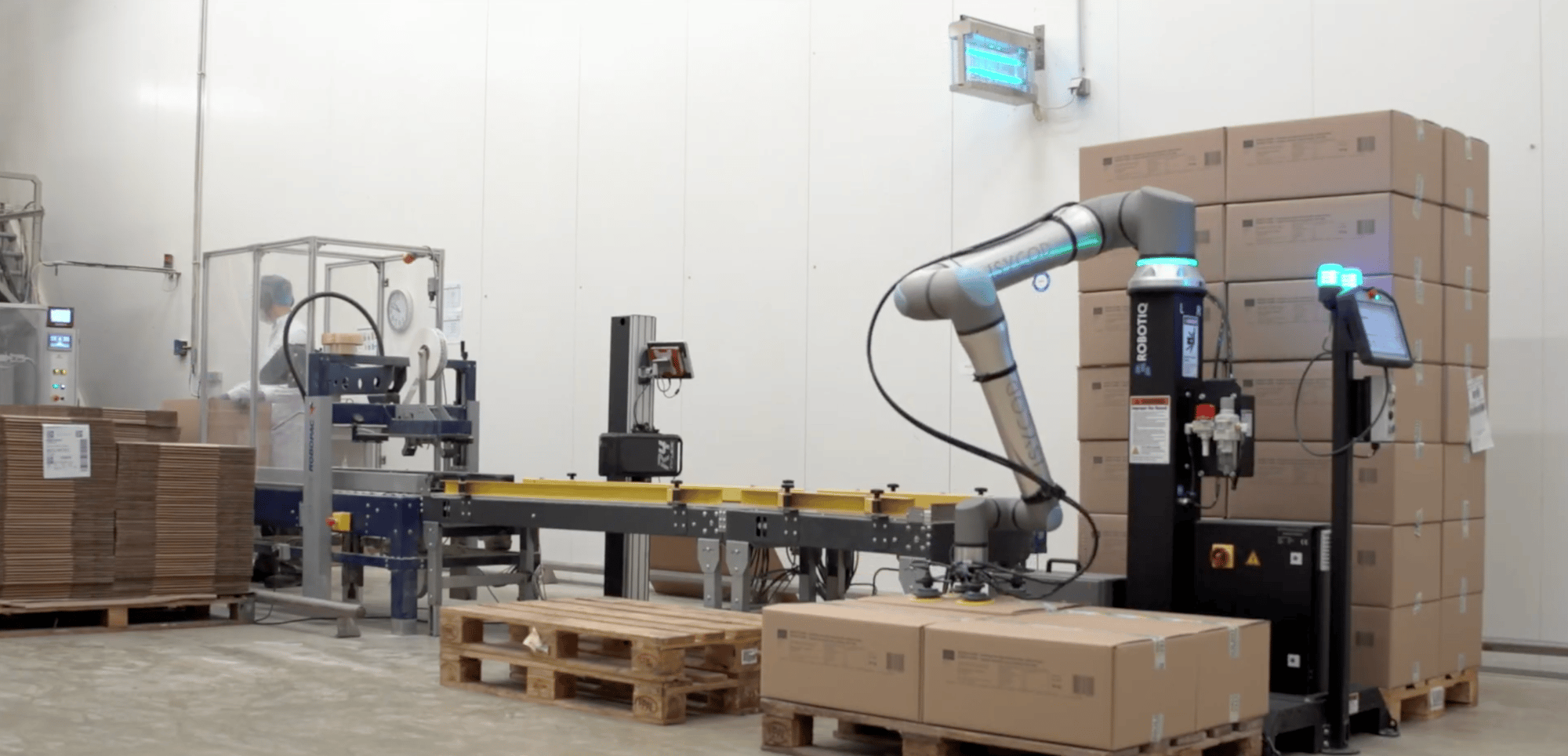

Biolintec deploys a palletizing solution in record time, reducing the risk of MSDs and increasing throughput

10 kg

boxes to palletize

1-hour

training

2-day

installation

About Biolintec

Founded in 2009, Biolintec is a specialist manufacturer rooted in the heart of France, dedicated to the production of a variety of soy-based products such as textured soy protein and micronized soy flour. Committed to sustainable development, Biolintec ensures that all the beans used in its products come from certified 100% organic materials, with an emphasis on non-GMO practices. The company is proud of its tradition of quality and organic integrity, making it a leader in the eco-friendly food processing industry.

Company Overview

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

The Problem

The main challenge for Biolintec was the manual palletizing process, which not only required a great deal of physical labor but also presented health risks for the workforce, particularly musculoskeletal disorders (MSDs). This problem was exacerbated by the weight and repetitive nature of the tasks, leading to increased employee fatigue, health problems, and difficulties in retaining a motivated workforce. Additionally, the company sought to increase the speed of their end-of-line process to enhance overall operational efficiency.

The Solution

In response to these challenges, Biolintec implemented the UR20-PE20 Palletizing Solution from Universal Robots and Robotiq in a record time of two days. This configuration was chosen for its ease of installation, operational simplicity and ability to efficiently handle large loads up to 25 kg. Key benefits included a considerable reduction in the physical strain traditionally associated with palletizing tasks, and increasing the palletizing station throughput.

Convincing wins with the Robotiq Palletizing Solution

ENHANCED PRODUCTIVITY

The introduction of the palletizing cobot marked a new era of productivity for Biolintec. The UR20-PE20 Palletizing Solution not only accelerated the rate of pallet processing, but also reallocated valuable human resources to more strategic tasks. This change has enabled the team to focus more on quality control and process optimization, making a significant contribution to the company's overall throughput and reducing bottlenecks in the production chain.

ERGONOMIC IMPROVEMENTS

The ergonomic design of the robotic system has played a crucial role in transforming the working environment at Biolintec. By taking on the physically demanding task of palletizing heavy loads, the system has considerably reduced the physical pressure exerted on workers. This reduction in manual labor has translated directly into a reduction in musculoskeletal disorder (MSD) injuries, which has significantly improved employee morale and reduced absenteeism. The health and safety of the workforce has improved remarkably, making Biolintec a better place to work.

INCREASED EFFICIENCY

The deployment of the cobot solution has enabled Biolintec to achieve unprecedented levels of operational efficiency. The technology has minimized the risk of manual errors, and reduced the downtime and the physical adjustments usually required in manual processes. This improvement in accuracy and reliability has ensured smoother, more consistent operations, enabling the company to meet production deadlines more efficiently and maintain a higher level of product quality.

The Robotiq solution

Palletizing

The UR20-PE20 solution features a user-friendly interface and a robust design capable of handling loads of up to 25 kg. It improves the accuracy and consistency of pallet placement of 10 kg boxes. The collaboration between Biolintec, Robotiq and Universal Robots, illustrates innovation in the automation of physically demanding tasks, improving productivity while ensuring worker safety and comfort.