Case Studies

DIEHL

DIEHL Aerospace expands quality testing capacity with 2F-85 Adaptive Grippers and an FT 300-S Force Torque Sensor

24/7

Quality testing

0

Jobs lost

1 year

ROI

About DIEHL

DIEHL Aerospace manufactures computer systems for the Airbus A350 XWB. With orders for this aircraft in full swing, their quality testing department needed to increase capacity quicklyProducts

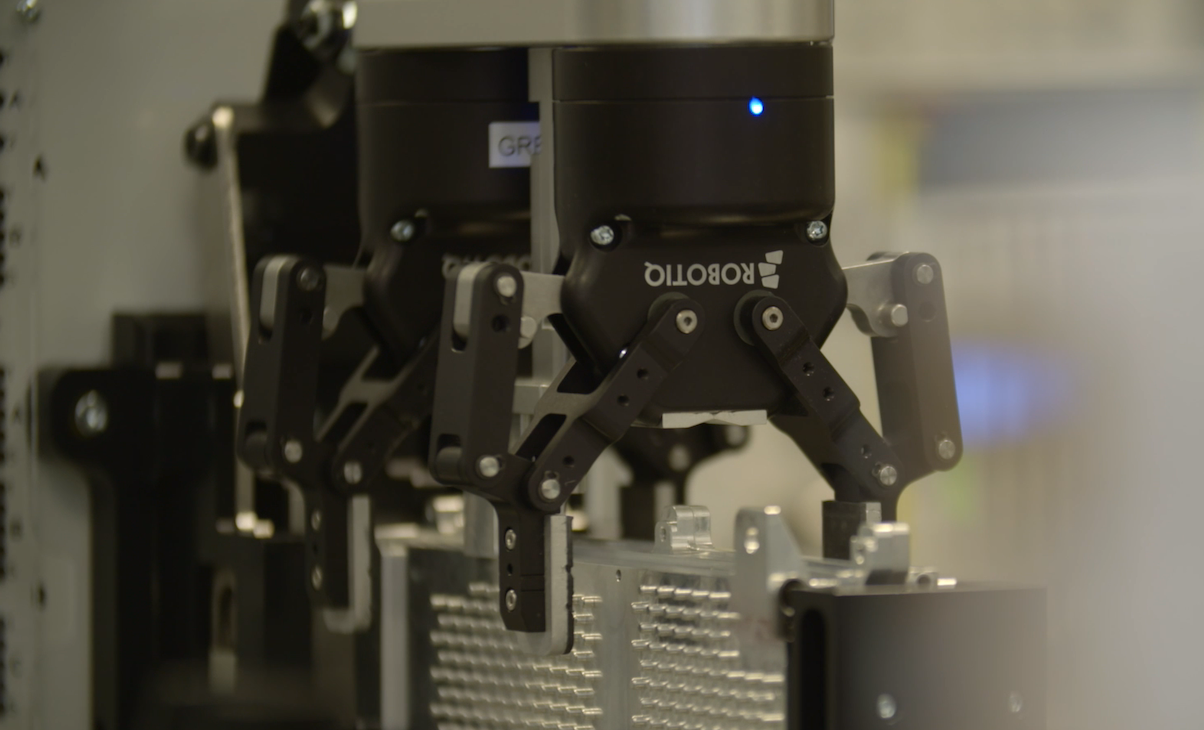

2F-85 Adaptive Gripper

FT-300 Force Torque Sensor

Quality testing

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Overcoming Challenges: Our Solutions

The Problem

Diehl Aerospace manufactures computer systems for the Airbus A350 XWB. With orders for this aircraft in full swing, the production capacity of the quality testing department needed to increase quickly. Management faced a choice between adding an expensive, permanent night shift, delaying deliveries, or implementing automation.The Solution

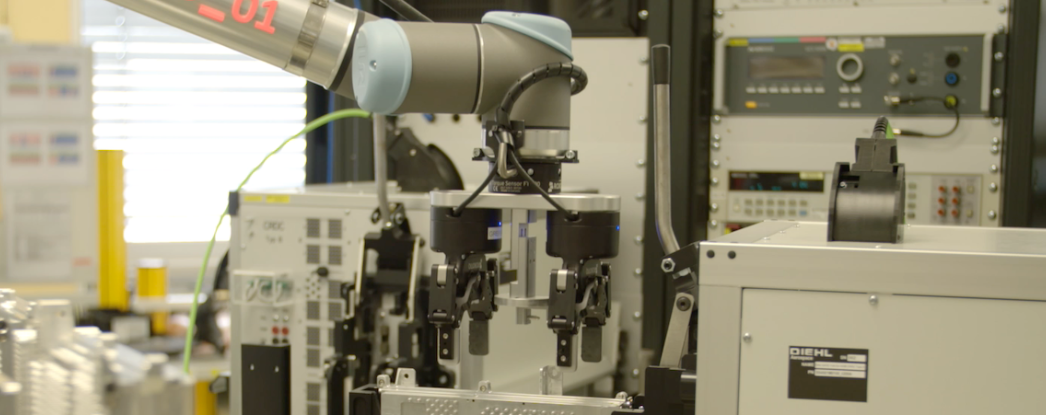

Diehl Aerospace chose a Universal Robots UR10 robotic arm equipped with a pair of Robotiq 2F-85 Adaptive Grippers and an FT 300 Force Torque Sensor to automate the computer’s final acceptance test. The robot is responsible for precisely inserting the fragile computer case into the testing hardware, wherein every electrical interface, input, output, and sensor is double-checked.

Complexity simplified.

Robotiq’s Machine Tending Solution brought benefits on many levels:

- Accurate quality testing: The 2F-85 Adaptive Gripper offered the flexibility that allowed to easily monitor force and the distance between two points. The Force Torque Sensor gives the opportunity to record complex movements with the path-recording function.

- A safe option: Diehl needed a solution that took little floor space in an open area. Diehl established a

- safety parameter with sensors that slow down or stop the robot when a human is detected within a specific distance from the robot. The highest standards of safety avoiding caging.

- Easy programming: Although there are many steps for the quality testing application, employees affected by the testing unit learned how to work with this new solution quickly.

The Robotiq solution

Quality testing

By implementing Robotiq’s quality testing solution, and adding capacity and reducing costs while maintaining the highest quality standards, Diehl Aerospace is now able to scale at the same speed as its customers.