Case Studies

Valero Group

Bread manufacturer Antic chose Robotiq Palletizing Solution over traditional automation

50%

Cost savings

4

Automated lines with only 2 robots

+30%

Production speed

About Valero Group

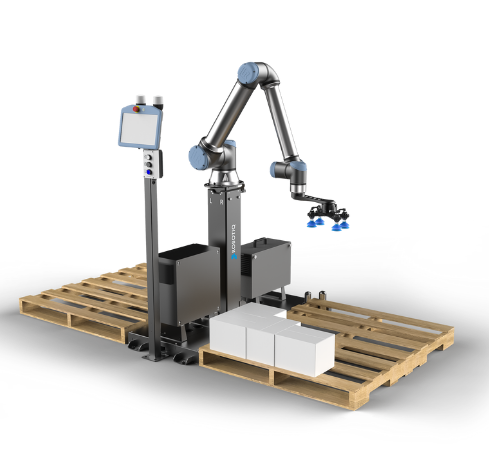

Antic, a leading bread manufacturer under Valero Group in Spain, specializes in pre-cooked bread, frozen bakery products and pastries. They have been distributing bread throughout Spain for over 60 years. Antic was confronting challenges in their palletizing processes. They were manually palletizing and looking for a scalable, automated solution that could adapt to different product weights and boost their operation’s speed. The solution also had to be easy to use and operator-friendly to allow on-site programming. Antic discovered the AX10, Robotiq’s transformative palletizing solution.

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Step 1 - Box dimensions, weight and orientation

Bread manufacturer Antic chose Robotiq Palletizing Solution over traditional automation

The traditional robot, the non-collaborative one, is on a different price level. And the collaborative ones, no one did for us what Robotiq has done.

Rafael Valero Beteta

Director of Operations

Overcoming Challenges: Our Solutions

The Problem

Antic was confronting challenges in their manual palletizing processes on two lines and they were looking for a scalable, automated solution that could adapt to different product weights and boost their operation's speed. Additionally, labor shortages were a looming issue.The Solution

Their search led them to Robotiq's transformative Palletizing Solution presented by our partner Vicosystems. They now run two automated lines and saved 50% in cost compared to their previous traditional automation project.

The Results

Convincing wins.

Robotiq’s palletizing cobot brought benefits on many levels:

- Performance: The implementation of AX10 led to boosting production speed by 30%, meeting Antic’s growing customer demands.

- Empowering people: Operators now enjoy a more streamlined operation. They are also empowered with a user-friendly system allowing easy product changeovers, and making them the true masters of their line.

- An adaptable solution: With Robotiq’s AX10 Palletizing solution, Antic successfully transformed their palletizing operation into a more efficient, scalable, and operator-friendly system.

The Robotiq solution

Being able to lift up to 12.5 kg, PowerPick successfully lifted 10.5 kg, surpassing expectations and further establishing the AX10 as a viable solution for Antic’s needs.

Applications

Palletizing

Robotiq’s AX10 stood out to Antic for its lifting capacity of up to 12.5 kg. This capability promised scalability, allowing Antic to lift 6-7 kg cases on one line and 9-10 Kg cases on the other line, with room to accommodate potential growth.