WHY AUTOMATE

Empower your people. Boost your factory productivity. Enhance your adaptability.

Automation is no longer optional

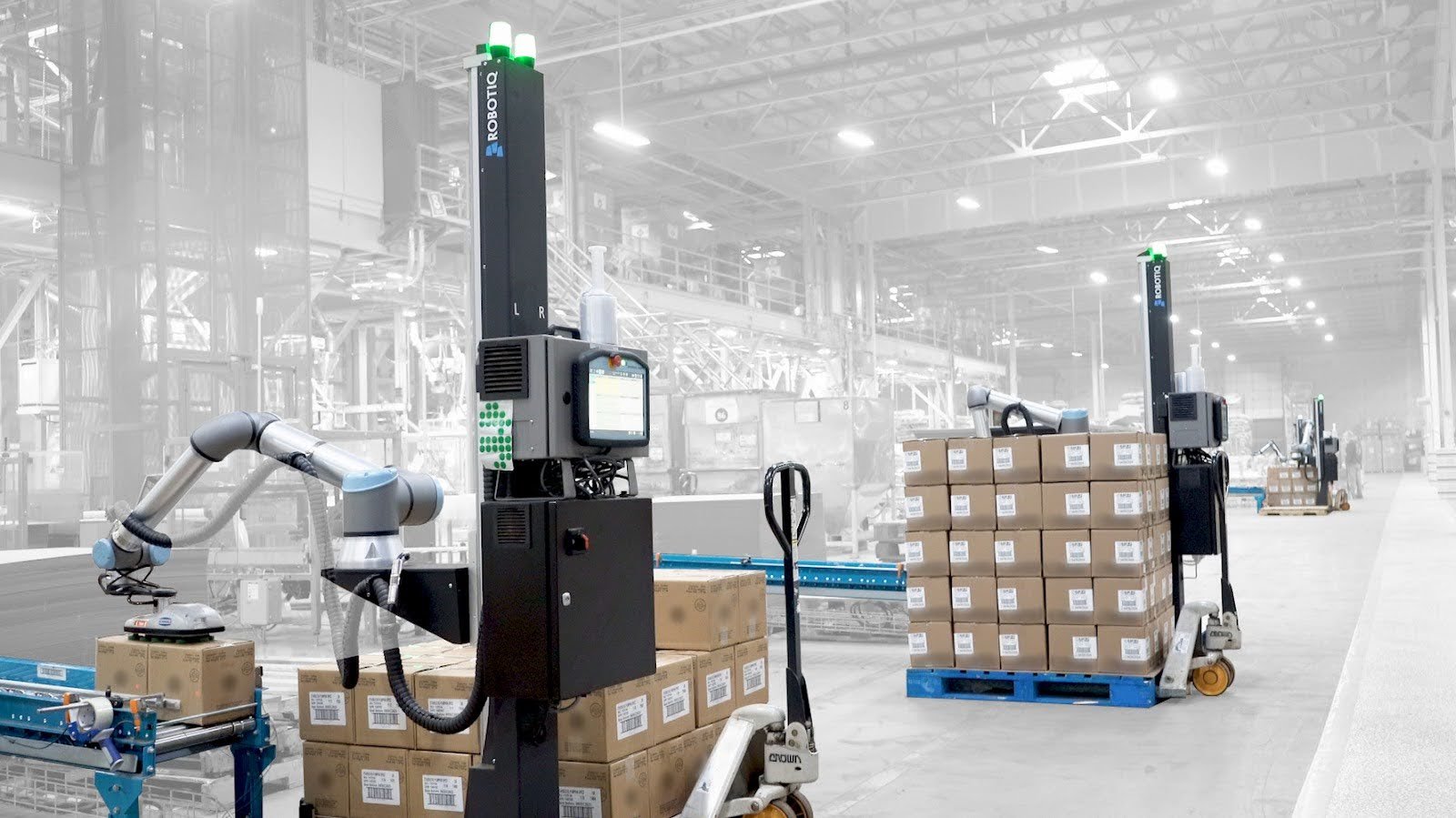

Manual operations are becoming harder to sustain. Rising costs, labor shortages, and safety pressures are making consistency hard to achieve.

Automation brings reliability, adaptability, and predictable ROI to modern manufacturing.

The cost of labor is rising

-

Labor costs keep increasing while skilled labor becomes harder to find

-

High turnover is reducing production stability

-

Physically demanding tasks expose teams to safety risks

Together, these pressures make manual operations less predictable, less safe, and more expensive over time.

Automation addresses all three—when it’s done right.

Productivity requires more than robots

Adding robots alone does not guarantee results.

The real barrier to automation has always been integration.

Traditional automation relies on:

- Custom engineering

- Expert-driven setup

- Long deployment cycles

- Uncertain outcomes

This makes it difficult to scale and hard to justify beyond isolated projects.

From Lean Robotics to automating integration

Lean Robotics provides a clear, step-by-step way to deploy automation, standardize what works, eliminate waste, and improve cost per output.

Automation must follow the same logic.

That means:

- Standardized building blocks instead of one-off projects

- Embedded intelligence that captures best practices

- Repeatable systems that deploy faster and perform predictably

This is how integration becomes simpler, faster, and more reliable—without turning every project into a custom effort.

Automation that adapts to the real world

Effective automation should:

- Improve safety by removing people from repetitive and hazardous tasks

- Deliver predictable productivity gains

- Adapt to real-world variability, not just ideal conditions

- Make economic sense from the first deployment to scale

When automation is designed with real factory constraints in mind, it becomes a practical tool—not a risky experiment.

Continue exploring

Whether you are navigating automation for the first time or looking to scale existing systems, the next step is understanding what’s possible today.

Discover Components

View customer stories

Benefits of automation with Robotiq

Enhanced productivity

Enhanced productivity

On average, manufacturers experience a 20-30% boost in productivity after implementing automation.

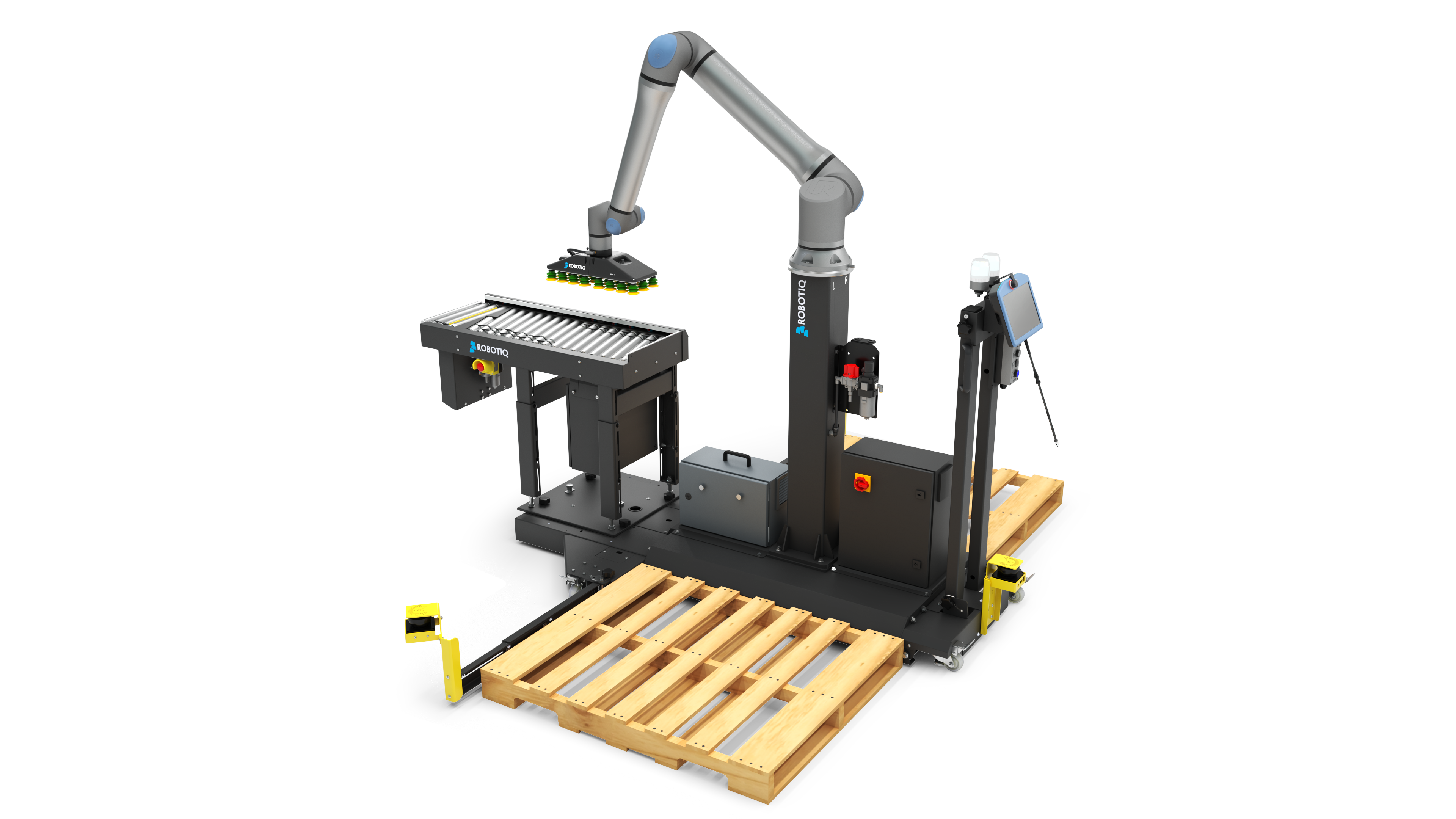

Seamless integration

Seamless integration

Following a lean manufacturing approach, implementing a Lean Palletizing workcell can be achieved in under 3 days with minimal training and no production interruptions.

Collaborative safety

Collaborative safety

Make your factory safer for your workers and reduce economic risks of injuries associated with repetitive tasks and heavy lifting.

Adaptive flexibility

Adaptive flexibility

Be fully autonomous in programming your workcell to meet changing demands and future-proof your factory.

Consistent quality

Consistent quality

Reduce manual errors, eliminate downtime and maintain uniform output.

Empowerment

Empowerment

Let workcells handle repetitive tasks, freeing humans for value-added activities. Offer jobs that people want to do.