WHY AUTOMATE

Win the manufacturing race with automation

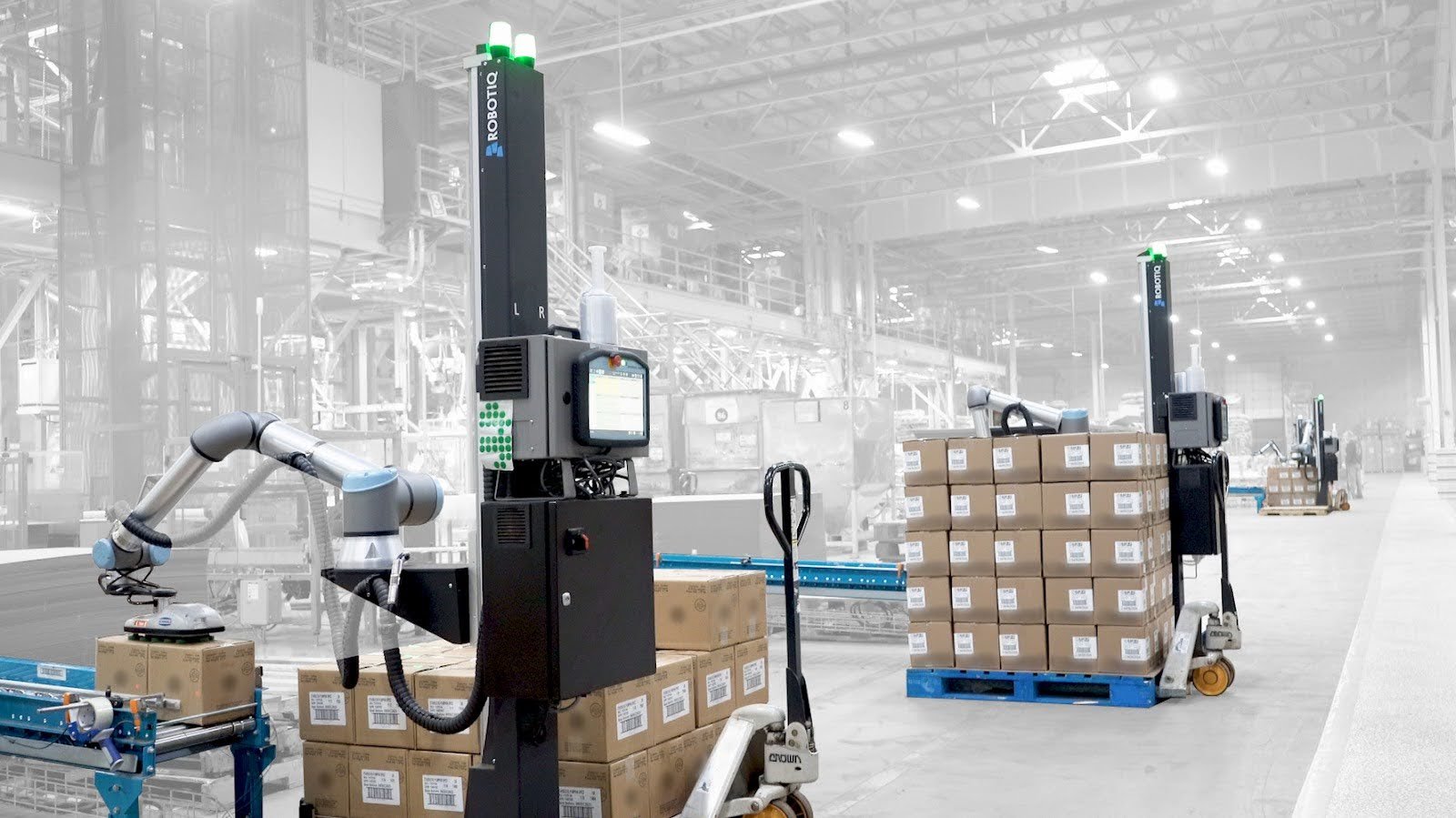

What's the difference between cobots and industrial robots?

Cobots, or collaborative robots, are designed to work alongside humans without the need for safety barriers, given the right risk assessment. They’re typically more flexible and easier to program, and they can be integrated into existing workflows with minimal disruption.

Industrial robots, on the other hand, are often larger, work at higher speeds, and require safety barriers for the protection of nearby humans. They’re best suited for repetitive, high-volume tasks.

Are cobots good for my business?

Cobots are not just instruments, but a valuable investment. With a modest financial commitment compared to other automation endeavors, they offer minimal risk and immediate benefits.

They adjust to meet your needs, so you can enhance productivity and optimize operations while earning a quick ROI (on average between 6 to 12 months).

And because cobots fit easily into any environment, their scalability is adaptable across multiple sites.

Are cobots safer than traditional industrial robots?

Yes, cobots are designed with safety in mind. They have built-in sensors and features that let them detect and avoid unexpected obstacles, including humans. This means they can safely operate alongside human workers without the need for protective barriers, given the right risk assessment. However, it's essential to ensure that any application they're used in is appropriately assessed for safety.

I have a small to medium-sized business. What kind of robot should I get to automate my palletizing cell?

There's no one-size-fits-all answer to this question, as the best robot for automating your palletizing cell depends on several factors unique to your business. However, the good news is that automation is no longer reserved for large companies. Small to medium-sized businesses can now effectively automate their palletizing processes thanks to a variety of available solutions. To help anyone considering palletizing automation make a clear decision, Robotiq has developed a comprehensive buyer's guide.

Benefits of cobot automation

Enhanced productivity

Enhanced productivity

On average, manufacturers experience a 20-30% boost in productivity after implementing cobots.

Seamless integration

Seamless integration

Following a lean manufacturing approach, implementing a cobot solution can be achieved in 3 days with minimal training and no production interruptions.

Collaborative safety

Collaborative safety

Make your factory safer for your workers and reduce your risks of injuries associated with repetitive tasks and heavy lifting.

Adaptive flexibility

Adaptive flexibility

Be fully autonomous in programming your cobot to meet changing demands and future-proof your factory.

Consistent quality

Consistent quality

Reduce manual errors, eliminate downtime and maintain uniform output.

Empowerment

Empowerment

Let cobots handle repetitive tasks, freeing humans for value-added activities. Propose jobs that people want to do.